Mixer conversion for Eifeler Betonbauteile

Eifeler Betonbauteile GmbH was founded by Gustav Balter in 1993. Over the years, the company developed a wide range of precast elements and custom components for rail track construction. After the reunification of Germany, the demand for precast components rose significantly due to the required expansion of the national rail network. Eifeler Betonbauteile GmbH manufactures its products in compliance with relevant rules and guidelines issued by Deutsche Bahn AG.

The company’s two strategically located production sites at Satzvey (in the western part of North Rhine-Westphalia) and Calau (in the south of Brandenburg) make it possible to serve both the whole of Germany and its neighboring countries, thus creating a high degree of flexibility for the operational business. Since December 2016, Nicole Werhausen has been managing Eifeler Betonbauteile GmbH and driving the continued modernization of the business.

Replacement of two mixers with skip hoists

All activities performed at Eifeler Betonbauteile are geared towards complying with relevant quality standards and ensuring customer satisfaction based on a number of certificates and tests.

To ensure continued adherence to this aim, Eifeler considered it necessary to upgrade its mixer systems to the current state of the art. Two mixers with skip hoists were thus to be replaced with new models whilst retaining the existing aggregate storage, conveying and weighing systems, as well as the currently installed cement silos. To implement this project, Managing Director Nicole Werhausen chose Pemat Mischtechnik GmbH, headquartered at Freisbach in the German State of Rhineland-Palatinate, as the partner to supply the specified equipment.

Patented whirler technology

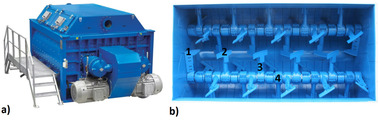

Aggregates are fed into one of the Pemat PMP 2250 planetary mixers or into a PMPR 1125 model via Pemat PAS skip hoists. The patented whirler technology enables exceedingly fast and perfect homogenization of the mix. Furthermore, the mixers are equipped with moisture metering and water dosing systems, which, combined with the innovative control unit, make it possible to achieve excellent repeatability for each mix. Each of the mixers is fitted with two outlets and discharges the material to one of the two newly installed bucket conveyors that transport concrete to two factory buildings. Like all other components, the Pemat PHR high-pressure wash-out system is integrated into the plant control unit; it ensures perfect cleaning of both the mixers and the bucket conveyors.

This custom mixer conversion project posed a huge challenge to all parties involved and thus necessitated close collaboration in order to succeed. Thanks to the commitment of all stakeholders, the new system was installed and put into service as planned, i.e. at the end of March 2018.