Modern Slip former plant for prestressed foundation piles

The Ukrainian construction company KhmelnizkZalisoBeton (“KHM”) – produces hollow core slabs with a Finnish extruder production line, and reinforced foundation piles made of wet-cast concrete in molds. Up to 4,000 foundation piles are needed for each project, and the existing production method could no longer meet the requirements for high capacity production while respecting design tolerances.

At the end of 2012 KHM visited Weiler GmbH in Gau-Algesheim, 60 km away from Frankfurt airport, looking for an advanced foundation pile production system. KHM required a daily capacity of 1,000 linear meters of foundation pile with cross sections 30 x 30 cm and 35 x 35 cm and lengths up to 18 m. The new system plant had to fit into an existing hall.

During a second factory visit in Gau-Algesheim, Weiler demonstrated on its own test track the new Multi-Caster to KHM – using dry-mix concrete. The visiting team of KHM experts was convinced, leading directly to a handshake deal!

Customized & tailor-made Solution

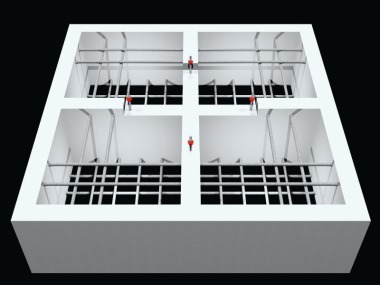

Weiler engineers designed and installed the new Weiler Multi-Caster line into an existing hall with 24 x 100 m of floor space. On 6 steel casting beds, each 96 m long, foundation piles and lintels are being slip-formed continuously, using the new Weiler Multi-caster with 3 quick-exchange cartridges.

After only 8 hours curing time the products are cut to the required lengths with a high performing Weiler concrete saw.

After lifting of the cut elements, the production beds are cleaned with an LPG motor driven Weiler “weasel” – this machine also sprays demolding oil and pulls pre-stressing wire.

Production targets surpassed

By April 2014 KHM took over the plant, ready for operation. Today, with only 8 operators, up to 1.700 linear meters of foundation piles are being produced in a single shift operation.

Shorter curing times, significant material savings, substantially higher performing final product, reduced steel content, minimized need of cement – approximately 200 kg cement less per m³ of concrete means approximately 2.500 euros of savings per day! – these are concrete hard benefits! KHM’s production chief commented on the results very directly: “That’s simply great!”