New Termo Deck system for Botswana

In early 2014, Spiroll were contacted by John Durham, Managing Director of Termo Deck International Ltd., regarding a project in Gaborone, Botswana.

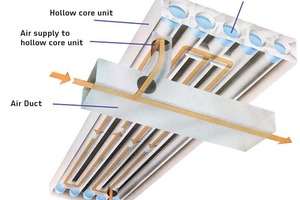

Termo Deck is a system, pioneered using Spiroll hollow core slabs, that is integrated with the heavy structure of a building. Instead of traditional steel ducts, the voids in the precast concrete slabs can be used to exchange air from the supply into the rooms, increasing the effectiveness of the building’s thermal mass. A big advantage of Termo Deck over other energy saving systems is that no additional equipment is required; therefore the overall construction cost does not increase when compared to conventional methods.

It has been used in different climates around the world, and is intended for use in new buildings. Overall benefits are savings in energy consumption of between 20 – 50 % and a reduction in peak cooling loads of 70 – 90 %.

Part of the Botswana Excellence Strategy

The project in question is the Botswana Innovation Hub, part of the Botswana Excellence Strategy. Proposed in 2008, it announced national strategic goals of economic diversification, job creation and movement towards knowledge based economy. Formed as a company to develop and operate Botswana’s first Science and Technology Park, BIH’s aim is to attract companies, universities, research and training institutes to help achieve these goals.

The project requirement for Spiroll was to specify, design and manufacture a production system to supply 40,000 m² of hollow core slabs from an outdoor, site based factory. The slab depths required are 250 mm, 300 mm and 340 mm with a non standard width of 1250 mm. In order to fulfil this, the package of machinery included a Universal Extruder, with cassettes for the 25 cm and 30 cm slabs, and a special modification kit to manufacture the 34 cm slabs. An essential spare parts package was included to ensure continuous delivery on the contract.

Alongside the extruder, Spiroll supplied a Crosscut Saw, complete with an adaptation to allow simple angle cuts, Prestressing Equipment and Slablock Lifting Clamps for both factory handling and site fixing. The steel casting beds were manufactured locally with design support and a drawing package provided from the UK.

Once production was ready to start, support with commissioning and training was provided by Spiroll engineers. This relationship and support will be maintained through the duration of the project, and Spiroll are proud to be part of what will surely be an enduring legacy in the development of Botswana.