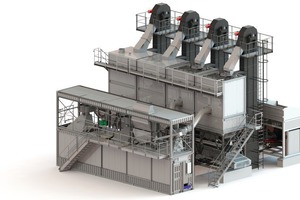

New concrete mixing plant and aggregate cooling systems

The German company Lintec GmbH & Co.KG, founded in 1919, has developed from its early beginnings in Berlin into a globally active group with production facilities in Germany, Poland, China, India, and Brazil. Today, Lintec offers a complete portfolio of concrete and asphalt mixing plants. At Bauma 2016, at Stand F12.1211/1, the company will present new developments in the area of concrete and asphalt plant and equipment.

Lintec mixing plants are built to 100 % conformity with stipulations, and in certificated ISO container form. This enables complete trial assembly before shipment and the possibility of accepting the plant on location at the production site, which results in considerable reduction to customers in transport costs and energy consumption. Expensive concrete foundations are not required for standard plant configurations; the modular concept provides for rapid assembly and disassembly. Safe access by an integrated stairway and complete encapsulation of the plant attest to environmental, health, and safety advantages that are leading in the sector.

Focus on mixing plant

The CC 3,000 B Lintec concrete mixing plant is a batch mixing plant with a capacity of 120 m³/h. This plant was developed to comply 100 % with ISO sea container design to ensure maximum mobility and rapid assembly, combined with high reliability and low operating costs.

Now as before, Lintec plant facilities are in operation for large-scale infrastructure proj-ects: for example, on Palm Island in Dubai, airport projects in Russia, onshore wind parks in Brazil, and soon for Europe’s largest hydraulic engineering project in northern Germany. This CC 3,000 B plant complies with international regulations and specifications and has been harmonized with the latest technical developments in software and electronics.

The ACS Lintec aggregate cooling system is a patented system. It operates in accor-dance with simple physical principles and enables savings of 50 % in operating costs for cooling concrete in hot and sub-Saharan regions.