New edition of a classic

Romano Classico is the trade name of a popular natural stone from the region around Rome. Since the antiquity, travertine stone has been used in many building structures and on public places. All over the world, concrete slabs manufactured in a wet-cast process with this particular natural stone surface magically provide the patio at home with a Mediterranean touch.

Wet-cast concrete slabs are considered as high-quality design products nowadays. In line with the trends towards spacious, elegant, and calm concrete slabs, Wasa has developed a new interpretation of cast stone in the design of Roman travertine.

From natural stone to master

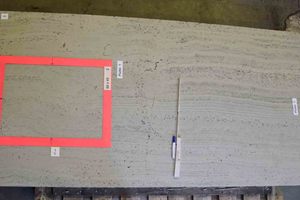

In the course of several journeys to Italy, natural stone slabs were selected at wholesalers for the implementation. These large-sized slabs showing the sophisticated travertine texture enable the later realization of cast stones measuring up to 2 m x 1 m. Soon upon their arrival at the south Thuringian factory in Neubrunn, the surfaces of the natural stones were cast with a silicone mat and secured.

To get a first impression of the appearance and the feel of the planned cast stones and cast stone systems, the large-sized concrete slabs are cast with the various silicone mats. The different surfaces and the faces for the stone systems are selected on the cast concrete slab.

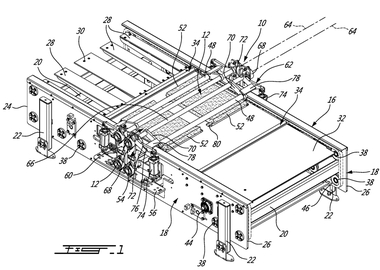

The travertine stone system, conceived in CAD, comprises four different sizes and each size has three different surface versions. The models are processed by CNC to achieve an elegant cast stone product with minimally rounded edges and narrow joints. When manufacturing the master, Wasa does not only pay attention to the visual appearance and the feel, but also to the functionality of the patio slabs. Sharp edges of the open-pored travertine texture that could lead to injuries when walking barefoot are smoothed and spackled at the surrounding chamfer. Due to a special surface finish on the model, the patio slab also obtains high slip resistance. The whole appearance of the stone system is reminiscent of a tumbled antique travertine, exactly in the Roman style, but nevertheless very modern.

Wet-cast molds made from polyurethane

The new travertine stone series was developed in cooperation with Greystone Ambient & Style GmbH & Co. KG, a subsidiary of the Lithonplus group of companies. Greystone replaced their existing travertine series and molds by the modern and sophisticated version of Wasa.

With the product launch in May 2017, two color choices are available for the travertine stone series. The customers can design their patio or grounds either in the pina creme shade or in the trendy anthracite shade.

The stone system will be continuously expanded by additional products such as pool edgings, garden bed edgings, and wall systems.

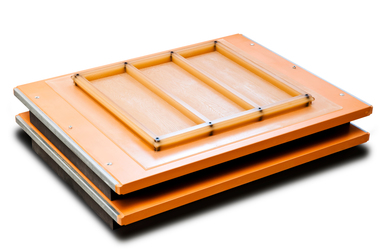

Wasa is not a new and unknown supplier to Greystone. Both companies have been working together since 2014. Particularly noteworthy for the quality of the Wasa wet-cast molds is the fact that patio slabs for the Timber series are now in the fourth year of daily production. The original polyurethane molds in the size of 1,000 x 250 x 45 m supplied in 2014 have been filled about 900 times until today. The Wasa molds remain stable in dimension and shape and are still in use.

Wasa at Intermat 2018

International customers can acquire the innovative and complete travertine product line as well as other European designs by purchasing the wet-cast mold; Wasa does not charge any license fee.

The mold design will be adapted to the existing or planned production plant. Demolding by means of a roller is widely spread in North America. Self-supporting and yet flexible polyurethane molds were developed especially for this technique.

Wasa will present its European design series and solutions relating to the subject of wet-cast on international trade shows, such as Intermat 2018, for the first time.

Text: David Werning