Wet-cast pioneer opts for Wasa molds

The Greystone Ambiente & Style GmbH & Co. KG company is a leading German manufacturer of wet-cast products. In 2003, Greystone started the manufacturing of patio slabs in serial production at the Eggersin location in the Federal State of Mecklenburg-Western Pomerania. The first fully-automated BFS Slabflex production line for wet-cast products was installed for this automated production process. In the course of time, Greystone has been building up an impressive range of concrete blocks and slabs in the field of wet-cast products.

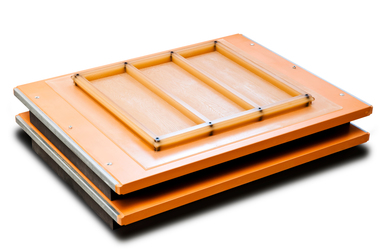

For the continuous development of this segment, in 2014, Greystone awarded Wasa a contract for the development and production of the slab system Timber as well as for the supply of new wet-cast molds for the cast concrete products which are already well established in the market.

Cast stones with

natural wood look

When being introduced on the market in March 2014, the initial daily production of Timber slabs could not supply the demand for the high-quality products. The production capacity was expanded in a fast and cost-efficient way by using additional wet-cast molds.

As far as large-scale slabs are concerned, Greystone makes also use of the comprehensive wet-cast range of Wasa. Therefore, the in-house modeling department developed and made models accurate to dimension with the aid of latest technologies such as CAD/CAM programs and CNC milling systems, starting from concept development up to the finished prototype. Polyurethane grades, which are designed exclusively for Wasa and specifically for the concrete industry, being made by means of ultra-modern process technology under vacuum, are used for the manufacture of the wet-cast molds. The high quality of the polyurethane grades used enables the production of wet-cast molds with a large volume, featuring extraordinary dimensional stability and long-life cycles.

Development

secured in the long run

Greystone is looking back on more than ten years of experience gained in handling of cast concrete products. Already in the development phase of the project, Wasa and Greystone discussed technical details and found solutions in close cooperation at eye level.

The investment made in the Wasa wet-cast system provides Greystone with sufficient development potential both for expanding the current product range and for adding further products to the sales program.