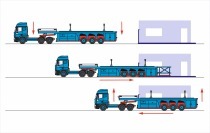

New inside loader for in-plant transportation

Langendorf, a manufacturer of inside loaders for many applications as a reliable and efficient transport solution. Langendorf has now supplemented its product line by another vehicle and offers a special-purpose inside loader for in-plant flat pallet transportation – the “Flatliner SBH-I.”

All flat pallets on the market can be safely and quickly moved – no matter whether the flats are loaded with precast products or paper rolls. The two-axle assembly permits small turning radii, the hydraulic axle balancing system permits rapid lifting and lowering.

The SBH-I generates most of all time savings by optimizing the in-plant flow of materials. The flat pallets, bearing the precast products can be quickly moved and positioned ready for pick-up. This, in turn, reduces the loading and unloading process on the flatliner readied for delivery, which only needs to pick up the flats and – thanks to the simple and quick load securing devices – is on its way to the construction site after only few minutes of idle time.

Flatliner SBH-I

The flatliner suitable for in-plant use has a payload of 36,900 kg and a tare weight of 8,100 kg. The loading width of 1,590 mm can accommodate flats already loaded with precast products up to 9,500 mm.

The vehicle is manufactured based on a flatliner used for the “field.” For its manufacture, the same quality criteria apply. Its undercarriage is manufactured from high-quality fine-grained steel sections and sheets in welded construction. The technically permissible axle load is 10.000 kg. It is equalized by a hydraulic suspension system. An additional mechanical safety feature prevents an uncontrolled lowering of the inside loader in transit.