Innovation: Flatliner SB 15

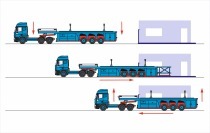

The trend in the construction sector is clearly towards prefab construction. Transporting these often huge elements is a challenge for the driver and the technical equipment. Using the Flatliner from Langendorf it is possible to load and unload prefab elements up to 3.700 mm height without need of crane.

The Inloader type SB 15–9.5, introduced at BAUMA 2016 trade fair in Munich, Germany, and used on all continents under the name Flatliner, features a number of design improvements. Constructed for use in conjunction with two- or three-axle tractor units, it offers the possibility to reduce unladen weight by around 500 kg through changing the specification.

Thanks to the proven and robust single-wheel suspension, the loading area has a length of 9,500 mm and a width of 1,550 mm. This makes it possible to transport loads with a length of more than 9 m and up to a total height of 3.7 m in the loading area.

Independent hydraulic system

Loads of these dimensions are normally transported by low-loaders but, as the case may be, often a special permission is required. Such movements, in most cases, are also subject to many provisions.

The hydraulic lift arm alleviates any special technical requirements on the tractor unit, giving fleets maximum flexibility when coupling the Inloader with most standard tractor units in their fleet.

The hydraulic system, as an option, can be operated independently by the electrical unit mounted in the trailer. The same electrical unit can also be used to operate three pairs of fixing devices hydraulically. They can be adjusted horizontally and vertically for the flexible adaptation to different loads and can be moved longitudinally on angular rails. For maximum safety, the system can be operated completely from the ground, to ensure the safest possible working environment for personnel.

Loading in less than 15 min

Seven pairs of lashing rings each rated at 5,000 daN allow multiple combinations of load to be secured safely. When driving unladen, up to five flat pallets can now be accommodated. The first and third axle can also be raised by means of a restraint system in order to reduce the tire wear and minimize rolling resistance, for improved fuel efficiency.

In addition there is the load securing device, which meets the VDI 2700 standard, as defined by TÜV Nord in May 2008. The driver simply has to take up the laden pallet and fasten it hydraulically by means of the fixing device on the Flatliner. After that he can commence his journey. This means that the complete loading procedure can be achieved in less than 15 min – TÜV tested and certified.