New rowing center on Rotsee with fair-faced concrete

Rowing regattas have been held on Rotsee near Lucerne since 1933. No wonder: It is extremely beautiful here and, with a length of 2.5 km, the lake is perfect for the international competition distance of 2,000 m. However, the infrastructure of the sports facility dated back to the early 1960s and was now so old that the Rotsee had no longer been considered as a venue for world championships since 2011.

In order to change that, the Naturarena Rotsee Association decided to have the infrastructure completely renewed. That meant not only erecting a new building, but also upgrading paths and open spaces along the shoreline.

The building

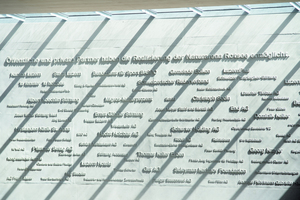

In order to be able to construct the new building, the old one had to be demolished first; only a period of just under a year remained for the construction of the new building. The result is a 60 meter-long timber building that sits atop two offset fair-faced concrete cubes. The entire building complex thus resembles a chocked-up rowing boat and offers a decisive advantage at the same time: since the upper structure protrudes beyond the lower structure, a roof is created that protects spectators and rowers against the weather. The concrete blocks themselves primarily contain storerooms. In order to reach the upper floor the visitor ascends fair-faced concrete steps, from whose landing he has a good view of the sponsors‘ wall. The names of everyone who contributed financially to the construction of the sport center are immortalized here in fair-faced concrete.

When planning the construction the architects attached great importance to making it possible to use individual areas of the building entirely independently of the remaining areas, because the object is actually only used for regattas for one month in the year. So that the operation of the building nevertheless covers the costs, the rooms are rented out for the rest of the year to a language school and to the Swiss Rowing Association.

Sponsors‘ wall

The construction of the new building cost CHF 11.2 million (approx. EUR 9.5 million) in total. Part of this came from donations from companies, associations and foundations. Their names have been immortalized on the 8.55 meter-long and 2.8 meter-high concrete sponsors‘ wall. This was made technically possible by formliners from NOE-Schaltechnik, with the aid of which fair-faced concrete walls can be given any desired structure. This means that they can be given the surface appearance of, for example, a natural stone wall or sawn timber or, as in this case, lettering. To do this the formliners, which are offered by the manufacturer under the name of NOEplast, must be fixed inside the formwork.

In the precast plant it is sufficient to lay them in the formwork. In the case of in-situ building sites, they have to be glued to the formwork or a support plate. If the formliner is glued to a support plate, the latter must then be screwed to the formwork. The advantage of this is that the formwork can then be reused later on. In order to meet its customers‘ demands NOE-Schaltechnik offers over 100 standard motifs, in addition to which there is a possibility for customers have their own wishes realized.

The planners of the rowing center made use of this option and had five formliners manufactured with the names of the sponsors. They chose the Replica Regular font. The size of the names on the concrete slab depended on the sum of money that the sponsors had contributed to the construction of the building. The arrangement of the names was determined by the planners. On the basis of this data, NOE-Schaltechnik first of all made a model by milling the lettering out of the hard-foam boards. The manufacturer then used this to manufacture the actual formliners.

Individual reusable formliners

The lettering „Ruderzentrum Rowing Center“ is already visible on the façade from afar. This too was cast in the concrete with the help of NOEplast. The manufacture of this formliner went a little differently, however. Whereas many small letters had to be implemented with the sponsors‘ wall, only a few large letters had to be manufactured for the facade. For this reason the NOE employees manufactured individual letters and fastened them to a support plate, with whose help the actual formliner was then cast. Since the formliners can be used up to 100 times it wouldn‘t be a problem, for example, to manufacture a further wall.