Pilot plant paves the way to the future

Implementation of a zero-waste economy requires feeding back of secondary raw materials into subsequent production runs, which is one of the major challenges all raw material processing industries are facing. This is particularly true for the German construction industry, which consumes mineral raw materials in large quantities whilst also generating the biggest waste stream.

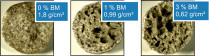

From a scientific and engineering point of view, lightweight concrete opens up the potential for establishing a closed material cycle. For this purpose, further advances need to be achieved in the development of recycled lightweight concretes on the basis of recycled lightweight granular materials and recycled lightweight concrete rubble. It is thus essential to conceive an innovative recycling technology that enables the manufacture of premium recycled products from previously non-recoverable fine fractions from the pumice industry, pure lightweight concrete, and lightweight concrete rubble from demolished buildings. The latter contains secondary constituents typically found in the construction sector. Possible finished products include recycled lightweight granules with defined properties that can be adjusted by setting appropriate raw material and process parameters. A large number of preliminary tests showed that the characteristics of such granules were comparable to those of commercially available expanded clay products. Recycled granular materials should be used as lightweight aggregates in new production runs of lightweight concrete blocks, thus closing the material cycle.

In recent years, experience proved that the rapid transfer of innovative recycling methods into practice has often failed due to the lack of a multi-purpose reference plant. IAB Weimar will be installing such a pilot facility to close this gap between applied research and industrial implementation. This new resource efficiency center of excellence will cover all relevant process steps, including crushing of construction waste, grinding, granulation, and firing in the rotary kiln. It will be available for industry partners to conduct joint research and tests.