Purely mineral concrete perfection in the micro-range

Every concrete specialist, architect, and builder assesses the visual appearance of architectural concrete surfaces in a different way – despite the fact that codes of practice and classifications into different quality categories do exist. But it is always a matter of opinion as to how vivid or homogeneous a client in the end envisions the appearance of concrete. I always recommend that the architect sits down with the responsible parties to determine the desired concrete optics, and only then awards the processing company a specific contract. This is the only way for both sides to obtain a result that satisfies both.

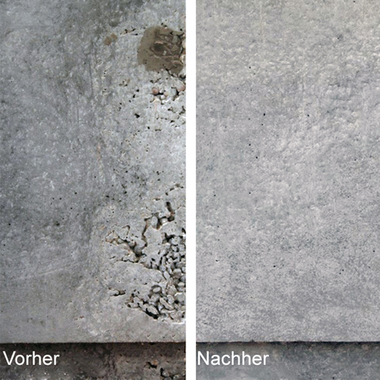

Where demands on the optics are modest, standard repair mortars that every builder has are used for correcting minor faults such as holes or gravel pockets. Where more exacting optical demands on architectural concrete must be satisfied, concrete cosmetics specialists are often consulted who can repair architectural concrete with their own special color tinctures, cement powderoccur, or glazes.

Differences in color that occur in the course of installation can always result due to differences in temperature, processing errors, and subsequent efflorescence. Existing concrete cosmetics systems based on glaze or color are not suitable for use on concrete floors and stairs because colors and glazes are not sufficiently resistant to wear and abrasion. With purely mineral concrete cosmetics, even heavily frequented floors and stairs can be durably repaired.

With the purely mineral concrete cosmetics system, concrete is repaired with concrete. The concrete formula is so finely adjusted that it, as described in the title of the presentation, can in the micro-range even be processed with a spraying device. With this processing technique, large concrete surfaces, even colored ones, can be quickly repaired.