Rapid hardening, also in wintry temperatures

Cold, snow and ice are special challenges that building contractors face in winter. Special concrete admixtures from Master Builders Solutions makes casting possible, also in wintry temperatures.

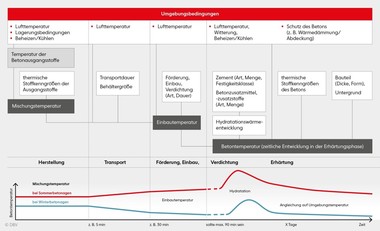

At temperatures of below +5 °C, concrete hardens noticeably longer, since the chemical reactions required for it (hydration), then nearly stops entirely. Therefore, additional heat supply is required until the concrete attains the necessary strength. This method, however, is both time-intensive and costly and may under certain circumstances adversely affect the final strength of the concrete, as well as its durability.

Considerable acceleration

of the hardening process

The concrete admixture Master X-Seed accelerates hardening and, at the same time, ensures the durability of the concrete. The accelerated hydration reaction warms the concrete from the inside, obviating the need for gas or diesel-operated heat sources, and reduces costs as well as lowering CO2 emission. Master X-Seed is suitable for use in concrete in accordance with DIN 1045-2 and contains very fine synthetically produced calcium-silicate-hydrate crystallites that ensure high early strength. This results in a considerable acceleration of the hardening proc-ess, primarily in the early state of cement hydration.

An additional advantage of Master X-Seed is that it, in contrast to conventional accelerators, retains the rheological properties of the concrete and does not influence the hardening process of the concrete until shortly before initial hardening sets in. “The processing time for transport and installation can be easily adjusted, and self-compacting concrete can be reliably used also in wintry conditions,” explains Markus Kroneder, head of BASF Business Unit Concrete Admixtures in Austria.

Time pressure no problem, even in winter

Master X-Seed is especially well suited for projects that must be completed under time pressure and in adverse weather conditions, as projects in Scandinavia have already shown. Another example is the gallery “Fallender Bach” at the Inntal motorway near Schönwies in Austria that could be re-opened for traffic in time for winter travel already shortly after unexpected rehabilitation work had to be carried out in December 2013. The concrete installed at outside temperatures of between +5 °C and -5 °C attained its early strength of abut 3 N/mm² already after ten hours. Without Master X-Seed, a value of less than 1 N/mm² could have been achieved in that time, in addition to the longer shuttering times and a noticeably slower construction progress.