Recent projects using precast concrete elements in Spain

ANDECE presents in the magazine CementoHormigón a series of recent works in cases where the use of precast concrete elements has contributed to the latter to meet requirements such as faster execution, better control of all processes, a drastic reduction in the generation of waste and a more aesthetically pleasing appearance.

One of the distinctive features of the current construction is the growing demand for solutions that ensure the sustainability of the works. In the case of projects that more or less incorporate precast concrete elements, an optimal sustainability is achieved mainly by seeking greater durability and better efficiency of all processes throughout the stages prior to the asset‘s commissioning (starting from design, through manufacturing and up to assembly). In addition, another growing factor is a greater digital component, which in the case of precast concrete elements is by the increasing using of BIM tools from the design stage that enable virtual modeling of the work and precise definition of the geometry, final position and technical features of each element.

ANDECE presents a series of recent works in cases where the use of precast concrete elements has contributed to the latter to meet requirements such as faster execution, better control of all processes, a drastic reduction in the generation of waste and a more aesthetically pleasing appearance.

1 Infrastructure

1.1 Bridge structure over the Más de los Arcos -

L.P. Castellón (Fig. 1)

Precast concrete elements used (type of concrete in each case): Lightened piles using expanded polystyrene in octagonal section (HA-60), headers, prestressed double T-beams (HP-50), deck precast slab (HP-40) and cantilever plates (HP-40) manufactured and supplied by Precon.

Abutment of precast reinforced floor panels, supplied by Alvisa,

Construction Company: UTE Acondicionamiento Mirambel = Construcciones Lecha + Romero Polo + PAPSA,

Project Engineering: FHECOR Ingenieros Consultores.

1.2 Bridge capacity expansion using box culverts (Fig. 2)

In recent years, the Department of Infrastructure and Transport of the Generalitat Valenciana has undertaken the improvement of the layout of the CV-14 road in the Castellón province. One of the recent works awarded to the UTE Conservación de carreteras, a joint venture formed by the companies CHM and OCIDE, entailed the widening of an existing bridge by placing 6.50 linear meters of box culverts. Tubos y Prefabricados Palau was in charge of the calculation, manufacture and supply of said box culverts, in accordance with the load conditions of the IAP-11, the backfill over the box culverts (1.18 m) and the interior dimensions (8x5.1 m).

The precasting company‘s technical department suggested the use of segmental box culverts comprising two parts with internal dimensions of 8 m wide and 2.55 m high. In addition, wall thicknesses of 0.60 m at the top and bottom and 0.40 m at the sides were proposed. With a length of 1.30 m, each half box was manufactured with HAC-40 self-compacting concrete and a weight near 24 t.

1.3 Pipes and other precast components for storm

tanks (Fig. 3)

Innovation and ongoing improvement are an essential part of many precast concrete product manufacturing companies‘ DNA. In this case we present the tubes and special parts that Arenzana Prefabricated has designed for a storm tank:

Receive pipes of DN 2,500 mm and collector pipes of DN 2200 mm

Capacities that can be sized according to customer needs, 400 m3, 800 m3 or 1,000 m3

Total watertightness guarantee by supplying the tubes machined by numerical control, milling the male end with a groove to house the rubber gasket. Total watertightness guarantee even below the water table level.

2 Buildings

2.1 Precast concrete panels for the largest resi-

dential complex in Spain (Fig. 4)

Aedas Homes is promoting the Hacienda del Rosario project, the largest residential complex with more than 1,200 homes, which will be distributed among the seven buildings that will make up this large development located to the east of Seville. One of the distinguishing features of this major project is the 36,000 m2 of façade of the first two blocks already completed, entirely made up of precast architectural concrete panels in white color and smooth, curved formats, ranging in thickness from 12 to 8 cm, and window openings, louvers and ventilation grilles. Panels manufactured and supplied by Prefabricados Hermanos Quijada. Executed by Sanjosé Constructora.

2.2 GRC, or how to lighten concrete effectively for

façade cladding (Fig. 5)

GRC (glassfiber reinforced concrete) has evolved relentlessly in recent years, and is increasingly becoming the preferred choice of many architectural firms for exterior façade cladding, due to the enormous aesthetic and functional possibilities offered by this material. Together with Daniel Padron & Asociados, Arquitectos SL and the construction company Satocan, the Antonio Afonso group built a new public school on the Canary Islands. For the cladding of this modern and accessible educational infrastructure the GlassyDurPana panel was chosen. A highly resistant GRC precast product with insulating qualities, both thermally and acoustically.

2.3 Residential with different precast concrete

elements for façade and structure (Fig. 6/7)

Houses built by Construcciones San Martín where Viguetas Navarras has supplied the following precast concrete elements: Double wall, precast slab and façade. Architect: Ángel Munarriz. Neighborhood Ripagaina located in Pamplona, an area rapidly growing in the south of the city.

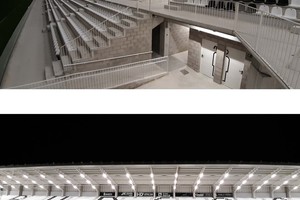

2.4 Stadium remodeling with concrete blocks

(Fig. 8/9)

Concrete blocks continue to represent the perfect merger between a traditional construction product and the potential to work with the most universal and versatile material. The Madrid Architects Association has recognized the remodeling work of Estadio Municipal de El Plantío in Burgos, in its COAM 2020 awards. Bloques Barruca‘s gray smooth concrete blocks were used in this project, requiring additional features such as compressive strength of 10 N/mm2 (category R10) and fire resistance EI-180.

3 Urban development

3.1 Development of drainage pavement solutions (Fig. 10)

Flooding caused by rainfall can have a huge environmental and economic impacts. To help to minimize its effects, Breinco has developed Filtra slab, a permeable pavement that incorporates drainage to manage rainwater. The combination of paving and drainage ensures a pleasant natural aesthetic of infinite lines, provides comfort to pedestrians and increases the permeability percentage up to 24,000 l/(s x ha), in addition to having the ability to reduce pollution and an enormous resistance to wear and tear. Its use is ideal for parking spaces, accesses and rural roads.

3.2 Pavement resurfacing to increase pavement

service life (Fig. 11)

In the port Molinar Marina in Palma de Mallorca, the construction company ACSA has carried out this remodeling with the main purpose of extending the durability of a pavement subjected to heavy wear and tear. For this purpose, the company Paviments Lloseta has supplied 3,000 m2 of concrete tiles of the Duromarés model, in 30x60x8 and 40x60x8 cm formats, yellow color and Durobrill treatment, which prevents from efflorescence and absorption, high-strength anti-slip texture. Its use is intended for paved areas with pedestrian traffic and light traffic, such as promenades, terraces, sidewalks, squares, boulevards, gardens, etc.

3.3 Precast concrete walkways for the improve-

ment of beach accessibility (Fig. 12)

The Municipal District of Vera (Almeria) has about 5 km of coastline, which main feature is that it is entirely a fine sandy beach, with an average width of about 200 m, so you have to walk a long distance on the sand to reach the seashore. Until now, the entire coastline has been equipped with wooden walkways, but their greater deterioration (weather, wear and tear due to the transit of people, maintenance and cleaning vehicles crossing them, and even vandalism) requires major investments in repair and maintenance. To solve this permanent problem, extending the durability of the walkways as long as possible, AG Premoldeados has designed and manufactured precast concrete slabs (HA=50), waterproofed and colored in mass, with a surface texture that resembles wood itself, but with the differentiating features of concrete.

4 Summary

In this summary of works with precast elements in the first half of 2021, we have tried to highlight the advantages offered by this construction technology, in a context of growing demand for increasingly industrialized solutions. Whether for the construction of buildings, the creation of civil engineering infrastructures or the development of urban areas, the common denominator of precast concrete elements is greater control throughout all phases of the construction process.

In addition, the increased involvement of the precast company - who knows best the products it manufactures - in the decision-making processes with the architect‘s office, the developer or the contractor, as well as its subsequent performance in the completion of the structure, is becoming increasingly important in order to achieve the specifications of each construction project, both in terms of its functionality and its aesthetics.