Reinforcement welding lines – Series PL X-Y and PLC AMM

Eurobend GmbH offers a comprehensive line of automatic machines covering every precast application: From the entry level welding lines producing simple reinforcing elements to complete lines producing engineering mesh, mesh with openings, mesh/rebar spacers, lattice girders, rotor straightening machines up to 25mm, stirrup bending machines in 2-D & 3-D etc.

The models of the PL X-Y and PLC AMM series are available for both small and high production rates and offer a very high level of flexibility without the need for adjustments

The latest mesh welding machines for the production of special, customized mesh and mesh with openings for use in wall panels are equipped with the unique feed system patented by Eurobend, which eliminates idle times due to wire diameter changes. Each mesh type can be produced immediately and without manual adjustments. This enables demand-based (just-in-time) production.

The feeding of the line and cross wires is done fully automatically by two Flexiline rotor straightening and cutting machines with extremely fast wire diameter changing system in about 3s (patented).

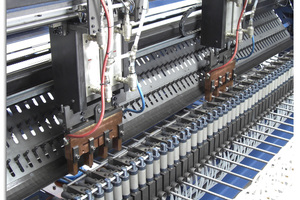

Eurobend realized programmable, servomotor-driven single or double Y-axis welding head configuration with 4 or 8 welding points per cycle (PL X-Y series) or multi-head configuration with up to 81 fixed welding heads (PLC AMM series).

Cold drawn or hot rolled material up to 20 mm from pre-cut bars or from coils can be processed.

Additional optional systems available include:

Fully automatic mesh bending modules that can be installed in line with the welding line to produce bent mesh;

Robot transport systems for the automatic transfer of the produced mesh to the circulating pallets;

Mesh buffer and storage systems.

The PLR Basic series

The modular design of these welding systems enables entry into mesh production at a low investment cost. Already established worldwide and known for their simple machine design, the reliable and cost-effective production of mesh in small series from pre-cut bars. Depending on the model, diameter ranges from 3 mm to 32 mm can be processed. All machine versions are equipped with independent and individually adjustable welding heads that cover different product widths and line wire spacing.

Line wires are fed from pre-cut bars, either manually into the welding heads or through a line wire pre-feeding carrier and where cross wires are fed automatically through a rack or disc-type feeder.

MELC Flexiline and Syntheton series

The flexible rotor straightening machines up to 25mm are ideal for order-related and just-in-time production.

Built into the Flexiline rotor straighteners is the straightening rotor with hyperbolic rollers invented by Eurobend. This has been further developed by Eurobend since the 1980s, so that can now proudly offered the patented fifth generation maintenance-free rotor straightener. This has eight rollers instead of the previous five or six and is maintenance free, eliminating the need for regular cleaning and lubrication. Straightening with these rotors has the advantage of excellent straightening quality without damaging the reinforcing steel ribs. This is why not only rebar processing companies rely on Eurobend, but also precast plants that require highest straightening quality and preservation of material properties without compromise.Diameters up to 25mm can be processed. Robotic coil opening systems and pay-off stations up to 10T complete the range. The rotor straightening machine with double bending function, the „Syntheton“, is perfectly suited for just-in-time order and demand-based production.

It combines the extremely fast diameter change system of the Flexiline rotor leveler with a fully automatic double bending function and is already in use at large precast plants.

The Flexiline principle in combination with an integrated, fully automatic double bending system with bending tool change in 1 s, the Syntheton series, offers a complete rebar processing center. Diameter changes and operating mode changes between the straightening machine and the bending stations take place automatically via the machine program.

All MELC Flexiline and Syntheton machines are equipped with the unique Eurobend convergence guide system for automatic diameter / coil change in approx. 3 s seconds without mechanically moving parts (patent). The extremely fast and automatic coil change and the bending toll change in 1 s enable the production of different reinforcement diameters and bending shapes in the same batch (order-related production). A flying shear that is common to all lines enables uninterrupted operation.

Stirrup bending machines - the G-Star Series

The extensive range of automatic bending machines from Eurobend, from coil or straight bars for the production of 2-D and 3-D stirrups and shapes, includes a number of different machine variants. Starting with the entry-level model of the G-Star Eco series up to the top models of the G-Star ASA & AWC Tris series, which offers, among others, automatic straightening roller adjustment and automatic diameter changing system.

Excellent straightening and accurate feeding without damaging the rebar ribs thanks to powered straightening rollers.

The lower rollers of the straightening blocks are driven and thus generate a positive, precise and evenly distributed feed force. The electrically adjustable anti-twist system always ensures flat shapes. In the case of 3D forms, the patented ATE system is also activated if required, whereby perfect 3D forms are produced regardless of the axial twisting of the reinforcing steel and the bending direction (patent).

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein (Nuremberg)/Germany

+49 911 94 98 980