Reliable surface protection for drinking water purification

In the heart of the Ruhr metropolis, the Rheinisch-Westfälische Wasserwerksgesellschaft (RWW = Rhenish-Westphalian Water Works Corporation) uses surface water of the Ruhr river as a raw water source. The water is purified in a multi-stage, multi-barrier process, the so-called “Mülheimer Verfahren” (= Mülheim process). Altogether, the Rhenish-Westphalian Water Works Corporation supplies water to around 825,000 people via a distribution network comprising around 3,000 km, making it one of the largest water service providers throughout Germany.

At the RWW’s Ruhr water works in Styrum/West, the raw water passes through a clarifier of type “Accelator”, which is the first step of the river water purification process. The Rhenish-Westphalian Water Works Corporation opted for an extensive refurbishment of the Accelator’s concrete surfaces. Many years of operation of this initial stage of purification had left their marks on the concrete structure with its slender concrete discharge channels.

Reprofiling with mineral mortar for drinking water applications

As some of the properties of water are aggressive to concrete, specific requirements applied regarding the internal lining of the surfaces. In addition, selected products only may be used which are approved for use in drinking water applications and need to comply with high hygienic standards. Many years of experience gained with surface protection systems enable Sika Deutschland, the Stuttgart-based manufacturer of construction chemicals, to offer a comprehensive portfolio of high-performance products related to the protection of drinking water and approved in accordance with current directives.

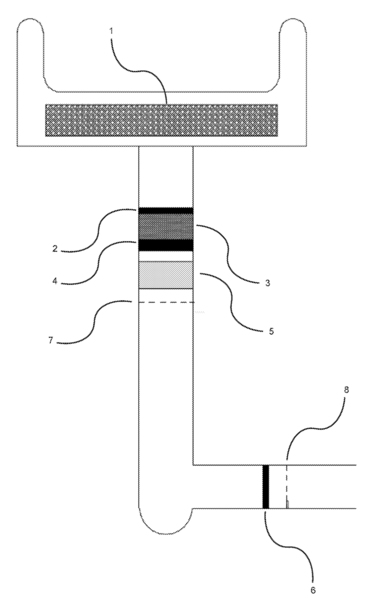

In a first step of the operation, a mineral mortar approved for drinking water applications was used for reprofiling. The hydraulically setting, two-component PCC mortar of type Icoment-540 from Sika was then applied in a subsequent step. The mortar serves as a thin coating of the drinking water tank. Its higher water retention capacity reduces shrinkage, which in turn reduces the tendency of shrinkage cracking. The Icoment-540 mortar was applied in layer thicknesses of 3 to 5 mm. Sika Permacor-136 TW, a blue-colored two-component epoxy resin coating, was applied in the next step of the operation.

The high degree of cross-linking of Sika Permacor-136 TW makes the coating resistant to water with a low pH value and simultaneous low carbonate hardness. The non-use of solvents during application of the coating eliminates both odor pollution and subsequent contamination of the water. After completion of the refurbishment operation, safe drinking water purification in the Ruhr metropolis is therefore ensured.