Sikagard-920 EpoCem repair mortar extends product portfolio

Moist substrates and pressurized water are causing again and again a problem at the construction site, for which Sika Deutschland GmbH offers a solution with the EpoCem technology: the existing portfolio is now extended by the Sikagard-920 EpoCem repair mortar. The thick-layer, highly resistant ECC mortar avoids osmotic blistering in case of moisture penetration from the rear side and can be applied on green concrete or concrete with backward penetration of moisture. Due to the high resistance to aggressive substances, Sikagard-920 EpoCem can ideally be used at wastewater structures. The EpoCem technology shortens construction times by at least one week as against conventional methods, thus allowing for quicker refurbishment at minimized waiting times.

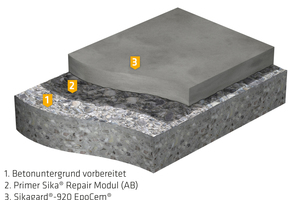

In the course of concrete repair measures, it is often difficult to apply synthetic resin coatings on mineral substrates because the moisture of the substrate frequently leads to delays in the construction process. Besides the option of elaborately drying up the substrate, using an ECC mortar or an epoxy-resin modified mortar as a temporary moisture barrier is a quicker and more cost-effective possibility. In this regard, Sika offers various solutions with the EpoCem technology. This can be an intermediate layer, fine textured mortar or a coarse mortar, which becomes generally necessary prior to the application of a reaction resin coating.

Combination of chemical and physical properties

Sikagard-920 EpoCem is a three-component concrete repair mortar. The two liquid components consist of an epoxy resin dispersion, and the powder component is made of cement and mineral aggregates. The chemical properties of the epoxy resin are combined with the physical properties of the cementitious mixture, thus allowing for the formation of a temporary moisture barrier. The high sulphate resistance of the mortar reduces the moisture near to the surface to <4 % CM. The temporary moisture barrier formed in this way can be overcoated by a diffusion resistant surface protection within seven days without the risk of osmotic blistering. Allowing a possible layer thickness of six to 30 mm, Sikagard-920 EpoCem is suitable for many maintenance measures, above all for wastewater structures.

EpoCem technology well-proven for more than 30 years

Repair works carried out on wastewater treatment plants can be expensive. The products used for renovation works therefore need to have an appropriate durability in order to extend the defined service life. As the Geesthacht wastewater treatment plant, for example, which was rehabilitated with Sikagard-720 EpoCem in 2000. The around 42 m² of coating in total are yet in perfect condition even more than 20 years later. The EpoCem technology has already stand the test for more than 30 years now and has proven its durability as in Geesthacht. Now, the newly developed Sikagard-920 EpoCem continues this track record.

CONTACT

Sika Deutschland GmbH

Kornwestheimer Str. 103-107

70439 Stuttgart/Germany

+49 711 8009-0