Retaining wall blocks used for Lanseria Industrial site

Retaining block walls have been used for the construction of extensive retaining systems and erosion control measures at one of the grass-root sites at Lanseria Corporate Estate, an environmentally sensitive industrial park, adjacent to Gauteng’s Lanseria International Airport in South Africa. Dubbed ‘One on 75’ and developed by Erf 844 Joint Venture, the project entails the construction of a plastic moldings factory which is due for completion in October 2021.

One of the Estate’s regulations is that all developments must comply with an approved JRA (Johannesburg Roads Agency) form of stormwater attenuation to prevent downstream flooding, erosion and pollution. In addition to two retaining systems, three attenuation ponds were built for the ‘One on 75’ project using retaining wall blocks supplied by CMA (Concrete Manufacturing Association) member, MVA Bricks.

Over 6,500m² concrete retaining wall blocks

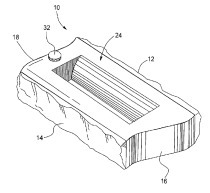

Over 6,500m² MVA 7 concrete retaining wall blocks were used to construct the attenuation ponds and the retaining systems. Two large ponds were built on the western perimeter of the site and a third subsidiary pond was sunk at the north-eastern corner.

“Although the attenuation ponds are unusually large, their footprint in relation to the overall size of the site is relatively small,” says James Croswell of Tribid Projects. “The north-western pond measures 50m x 20m and has 3,000m³ capacity; the south-western pond measures 75m x 15m and has a 2,000m³ detention capacity; and at 40m x 15m, the north-eastern pond has a water detention capacity of 1,500m³. Two further ponds will be built along the property’s eastern boundary when a proposed building extension is unveiled at some future date.

“This is the first time that we have used concrete retaining block walls exclusively for building attenuation ponds, and to save space, we made the ponds relatively deep. We looked at several building materials to meet our design criteria but in the end the MVA 7 block proved the most economical option.”

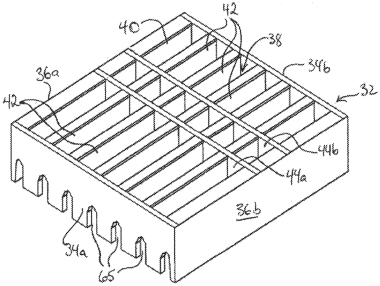

MVA 7 blocks and Slider Panels supplied by MVA Bricks

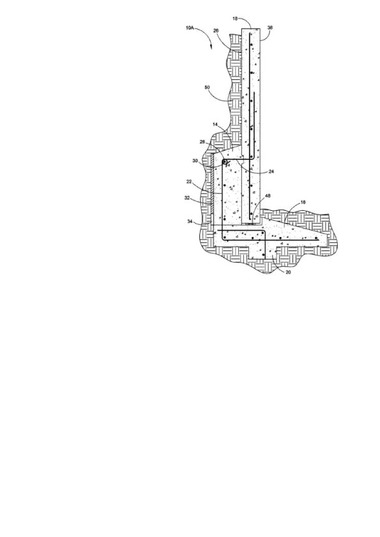

Both the pond and the building platform walls were built with the lower half of each in closed face configuration using MVA 7 blocks and Slider Panels supplied by MVA Bricks. The top sections were constructed in open face. Moreover, the cut-and-fill walls and the backfill in the attenuation pond walls were cement-stabilized. Maccaferri’s WG-6 geofabric was used to reinforce the fill material behind each wall at every fifth block course.

All the walls were built with 45º wick drains every 1.5m. They discharge into bottom drains and, in walls higher than four meters, into mid-level drains as well.

The ponds have a weir capacity which accommodates a 1:100-year storm event. All the water collected off the building and the concrete platform which surrounds it drains into both western ponds. Lined (Armorflex) channels have been installed along the bottom of the ponds to cater for low flows, and an overflow culvert was constructed at +1.5m for draining high outflows from the south-western pond.

“The gray water is partially purified through the removal of hydrocarbons by the vegetation which grows at the bottom of all the attenuation ponds on the estate. Each developed site is allocated a gray water quota at a ratio determined by its catchment area, and the water is pumped through a set of solenoid valves. Smaller sites use header tanks for storing the water whereas two 10,000l JoJo tanks will be installed at the ‘One on 75’ site,” said Croswell.