Easyblock, the innovative precast retaining wall

system – Made in Europe

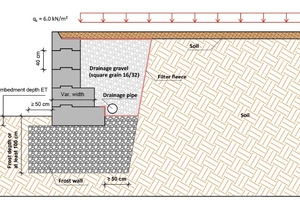

The easyblock GmbH based in Carinthia, Austria, is a start-up company founded in 2022 as a promising joint venture of two renowned businesses also based in Carinthia, Kandussi Holding and Hirsch Porozell. Austria’s geographical setting characterized by imposing alpine and low mountain ranges poses a permanent challenge to private and public sector construction projects that need to get to grips with the region’s elevation profile. This is where easyblock comes into play, a retaining wall and slope stabilization system developed in Europe. The concrete blocks’ modular design allows for straight, angular, curved, and stepped walls or slope stabilization structures such that the easyblock system blends perfectly into the landscape.

Three system categories

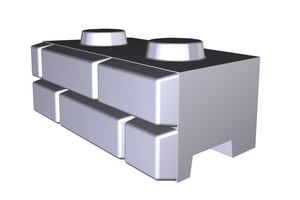

The easyblock system includes three distinct categories: the Base Block, the Standard Block, and the Top Block. Base Blocks are available in installation heights of 60, 90, 120, and 150 cm. In the 60 cm size, each block weighs 640 kg, while its heaviest version with a dead weight of 1,200 kg is designed for particularly high retaining walls. The concrete blocks excel with their quarry stone texture, which provides a genuine stone look.

Joining forces with Wasa

Various models and tools were developed to produce the textured form liners in collaboration with the Construct division of Wasa Compound GmbH & Co. KG based in Neubrunn, Germany. “We got the first project enquiry from Helmut Kandussi, Managing Director of easyblock GmbH, at the World of Concrete in Las Vegas in early 2022,” recalls David Werning, senior executive at Wasa Construct.

At that time, the entire project was quite far advanced already. The different types of blocks already existed as 3D models including all design details. However, easyblock’s preliminary tests with simple form liners did not meet the visual requirements to stand out from commercially available systems.

Integration into the Wasa CAD design tool

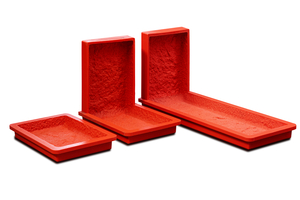

The virtual, true-to-scale 3D model data provided by the customer was seamlessly integrated into Wasa’s CAD design tool. During a joint two-day workshop, Wasa presented its mold solution and various possible textures for the product. The project managers opted for the Wasa Stonecast, Gneiss 3 category. The original quarry stone template is a large, coarsely textured mudstone slab.

When designing the model, Wasa did not just limit its work to creating a two-dimensional surface. To achieve a genuine natural stone look, the lateral textures were modeled in accordance with the design specifications developed by the in-house model-making department.

Rectangular corner blocks: a major challenge

The design of the rectangular corner blocks posed another major challenge to Wasa’s model-making workshop. In response to easyblock’s requirements, the final design was to ensure a seamless block without joints or unclean lines, which would otherwise be created by a two-part form liner.

The EPS molds include up to ten different form liner templates to achieve a range of different surfaces and a varied appearance of the concrete blocks. It was not only easyblock who were impressed by the implementation of the design specifications and the final result. Even during the prototyping phase, concrete block producers showed interest in adding the innovative system to their range.

International commercialization envisaged

The pronounced market interest supports the original idea of commercializing a retaining wall and slope stabilization system beyond the borders of Austria in licensing partnerships. While acquiring new customers, Erik Nelson, an architect by profession, was recruited as international sales director of easyblock.

“Key differentiators of easyblock include the pioneering use of EPS (polystyrene) molds in concrete block production and the faithful rendering of the quarry stone look using Wasa polyurethane molds, which will revolutionize the industry,” summarizes Erik Nelson.

In addition, easyblock has already begun to offer training courses, an app-based software for quantity takeoff complete with information on concrete block installation, project images, and a 3D model library for the license holders’ own CAD design.