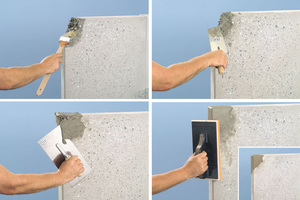

Saving time in repairing concrete

Ensuring the function of concrete structures and retaining their aesthetics – quickly, economically and reliably. Because the universal mortar StoCrete SM requires no bonding course, it can save up to 35 % in processing time and 60 % in waiting time, compared to conventional reprofiling systems. This makes reinstatement of damaged, no longer trafficable concrete components especially cost-efficient.

A rapidly hardening mortar such as StoCrete SM enables specialists to achieve optimal results efficiently. Owing to the high processing tolerance of the rapid-repair mortar SM, even challenging substrates can be reliably and easily repaired. Its application possibilities – both for reprofiling corner and edge breakage, and for applying levelling coats – simplifies the work. Workers especially save considerable time as a result of short waiting times – and by faster processing. Levelling coats with layer thicknesses of up to 40 mm can be realized in a single work step (fine filler, 3 to 5 mm). Application of several layers is also possible without difficulty. The potlife of StoCrete SM allows convenient overhead processing without the need for additional measures. Other advantages: its low modulus of elasticity enables use for concretes of low strength, and StoCrete SM can also be easily, reliably and rapidly processed in low outside temperatures beginning at +5 °C.

The StoCrete SM P variant, moreover, is a mortar with integrated corrosion protection that saves another work step compared to conventional processes. The advantages of both universal mortars, combined with their cost efficiency, add up to two effective all-around products for concrete repair.