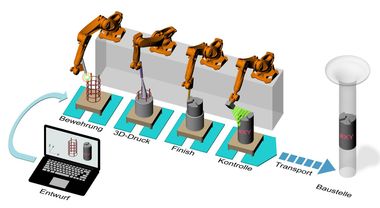

Shotcrete 3D Printing (SC3DP)

Additive manufacturing (AM) is a technology that opens up the potential to completely rethink the process of producing concrete components. In contrast, the conventional method involves the pouring of concrete into forms, and the associated costs of mold-making or formwork production have a major influence on design freedom as well as material consumption. In the past few years, the Shotcrete 3D Printing (SC3DP) process was developed at TU Braunschweig. This AM technology utilizes the free-form options provided by robotics-based manufacturing in order to place concrete in multiple layers so as to manufacture three-dimensional concrete elements. This fundamentally new manufacturing approach applies the material only where required for structural, functional or design reasons.

Unlike 3D concrete printing by extrusion where concrete layers are deposited upon each other, the SC3DP technique creates the concrete matrix by high-pressure spraying (shotcreting) in a layer-by-layer process (printing under pressure). This method achieves a very firm bond across the individual layers, with the associated positive effect on the properties of the material. The SC3DP technology is suitable for achieving a high degree of design freedom thanks to robotics-based manufacturing as well as for integrating innovative materials developed in recent years, such as ultra-high-performance concrete, so as to unleash their full potential.

This paper will outline the current development status of the SC3DP technology. Furthermore, in-depth research into reinforcement integration and surface finishing will be discussed.