Swiss metal trader builds with GFRP reinforcement

In the Swiss Plateau region situated at the border between German and French speaking Switzerland, a typical medium-sized enterprise has allowed itself a corner extension covering nearly 600 m². In this way, the company solves the problem of space shortage, creating meeting areas, office workplaces and a conference room. A steel reinforcement of the concrete core was out of the question for health reasons. Therefore, the Combar glass fiber reinforcement of the building product supplier Schöck was used as reinforcement, although the building owner is trading with stainless steel and metal.

L. Klein AG founded more than 70 years ago supplies customers across the world with high-quality special steels used, among other things, for watchmaking, in medical engineering, electronics, and mechanics. The existing warehouse building dates back to 1957, a brick building with butterfly roof. A two-story office wing was integrated into the rectangular floor plan at the warehouse‘s northwest side. In the course of time, minor extensions were necessary time and again, in the end, even as a container on stilts which was connected to the building on the level of the second floor. Hence, the aim was to put an end to this disappointing situation by a presentable extension as replacement.

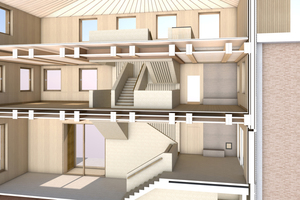

Hybrid building made from wood and white concrete

It was only in the phase of planning the wood construction of the replacement building, when the decision was made in favor of a high-quality Jura limestone concrete for the stair core; which again resulted in the decision not to use any steel as reinforcement for the same. In particular, in view of the building owner‘s aim to create a healthy workplace environment for the employees, it was essential to avoid electric smog and magnetic fields. Consequently, the extension is free of any electrical loop wiring systems, among others.

„Small but effective“ – this is how the three-story extension could be characterized, with providing some challenges for engineer, wood builder, and site manager. The open stair core with sculptural appearance supports parts of the column-free suspended ceiling made from wood. Special Bongossi wood inserts in the concrete shells were necessary for the connection between wood and concrete. The wood elements inside the building are connected by means of dove tails, tongue and groove as well as dowels – because, also in this case the general rule was: no metal, no steel. This is quite unusual for a company dealing in these particular materials.

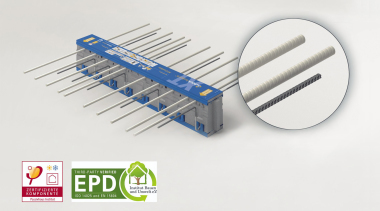

„Actually, we intended to erect a pure wood building,“ Philipp Schiess, member of the management board at L. Klein AG, says. „However, our conception in terms of space and architecture could be realized even better with a concrete core.“ Due to the use of reinforcement with glass-fiber reinforced bars made of vinyl ester resin there are no magnetic fields. The bars are corrosion-free and do not conduct electricity. Schöck Combar is suited to be used in floor slabs, ground slabs, foundations, walls, ring beams, lintels, and columns of single-family houses, apartment blocks and office buildings.

Apart from the main field of application in civil engineering, including tunnel and bridge construction, the construction of industrial and energy facilities as well as research institutes, the Combar glass-fiber bar is also used in general building construction. Used as tension bar in the Schöck Isokorb thermal insulation element for cantilevered structural components, the low thermal conductivity of 0.7 W/mK of the fiber composite comes into play, reducing thermal bridges to a minimum.