Twinmaster for new standards in coil processing

The times when closed stirrups or U-bars were tediously manually bent are long a thing of the past. Automatic stirrup benders have simplified these tasks for many years; many of which, however, are limited to standard forms. The increasingly frequently encountered shapes, bent-up on both ends, especially require an additional work step. Often, even the use of bar material, instead of coil material, must be resorted to.

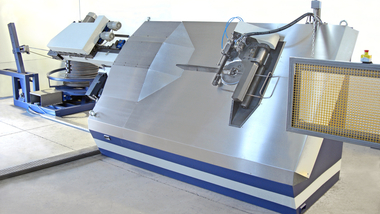

Decades of experience in reinforcement, steel processing from the coil is the basis for the next and best generation of Pedax stirrup benders. The Twinmaster 16X+ DB NEO combines all advantages of a modern plant with flexibility; long shapes bent-up on both ends can be manufactured in one work step.

Servo technology has proved its worth for many years

The Twinmaster 16X+ DB NEO is based on servo technology time-tested over many years. This not only environmentally friendly: energy-efficient technology is also at the heart of all Pedax stirrup benders. Hundreds of plants, in operation on all continents, are impressive proof of their robustness and reliability.

Two straightening units – one horizontal, one vertical – straighten in outstanding quality the coil material of 6 to 16 mm diameter. The Twinmaster 16 X+ DB Neo, unique on the market, processes 14-mm double wire, which leads to a tremendous increase in productivity. Because, after all, medium-diameters in particular are where the action is – an advantage that is immediately apparent in tonnage and consequently also in euros and cents. The main advantage of the Twinmaster 16X+ DB NEO lies in its double-bending unit. In combination with the closed bar shelf, double-bent shapes up to 12 m long and up to 1 m high can be produced in a single work step. This is achieved by an additional motor that drives the material feed system and by the bending head that turns 180 degrees to process both ends. A special feature is the pivotable work screen with the aid of which bending takes place freely and unobstructed above the shears and the covers, ensuring clean, closed stirrups.

The often unwieldy and bulky forms processed are easily picked up by a row of hooks, which is located directly adjacent to the bar shelf. An order-picking trolley that is cycled underneath the plant ensures placement in the correct position and a continuous production process.

New standards in coil processing

The optional wire magazine, in combination with motorized reels, designed for coil weights up to 5 tons, also easily manages changes in diameter. Conversion to the next diameter takes place by the push of a button to reconfigure the operator interface. Only the bending tools need to be exchanged by the rapid-change system, and processing of the new diameter can begin. And, if something really should go wrong, there is online access directly on the machine to eliminate downtimes.

The Twinmaster 16X+ NEO sets new standards in coil processing with the knowhow of Pedax to increase productivity and flexibility in the plant.