Innovations in the areas of reinforcing steel processing and mesh welding

At the upcoming bauma, the world‘s leading trade fair for construction machinery, which will take place from April 7 to 13, 2025 in Munich, Eurobend will be showcasing the latest innovations in the field of reinforcing steel processing and mesh welding in Hall C3/225.

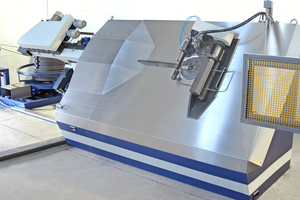

There will be presented, among others: The G-Star SP machine, a special stirrup bending machine designed for high-performance production of continuity system stirrups from coil. The latest servo technology is used here, ensuring reliable and cost-effective production. The G-Star SP processes diameters of 8, 10, 12, 14 and 16mm and offers a number of advantages:

Elimination of secondary bending operations.

The bending system employs one classical rotating bending plate with incorporated cutter and retractable bending pin and a 3D bending device with two bending arms that simultaneously bend both legs of the stirrup into the third dimension.

The second benders angle is adjustable with respect to the rod axis, for the different Continuity Systems Stirrups widths.

External bending support system for faster production of continuity system stirrups with tapered legs, with a total of three bending movements instead of five (patented).

G-Star SP series are standard equipped with electric Adjustable counter-torsion system always producing flat shapes (Patented).

Two types of straightening roller adjusting systems are available: the Hexagon Shaft Pre-setting System and the fully automatic roller adjusting system “ASA”.

The Spiral SP series of spiral benders have been developed for the high-speed production of precision square/rectangular shaped spirals (Patented). Four hydraulically operated bending heads mounted on a robust slide way achieve high output with excellent accuracies but most importantly, repeatability and consistent quality. The bending heads can be easily repositioned for different side lengths.

The Spiral SP series unique advantages include:

Reduced product costs in comparison to stirrups;

Massive space and labor savings;

Unlimited production flexibility;

Elimination in material waste;

Reduced installation and on-site assembly time;

Better structural protection;

Easier concrete casting.

Eurobend is looking forward to welcoming numerous visitors to bauma in Hall C3/225.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980