UHPFRC composite joints

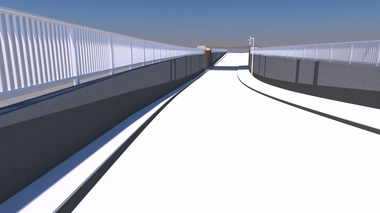

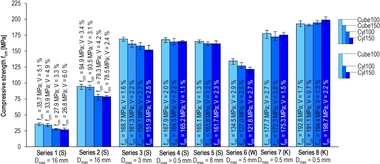

Ultra-high-performance fiber-reinforced concrete (UHPFRC) is a cementitious high-performance material which, through an optimized grain structure and added steel fibers, achieves a compressive strength in excess of 150 MPa and a tensile strength of approx. 8 MPa. The crack-bridging effect of the micro-steel fibers added (the so-called fiber effectiveness) results in a very fine crack distribution pattern at very narrow crack widths and thus excellent durability. The material’s properties make it eminently suitable for use in highly stressed, permanent and slender structures such as bridges or parking deck systems.

As special requirements are placed on the production of UHPFRC, it is recommended to use the material as a precast structure. This enables short construction periods to be realized and results in extremely cost-efficient structures. Joining the precast elements on the construction site requires a suitable joint design which is decisive for the structural behavior, assembly and durability of the structure. To prevent damage, the joint needs to be designed so that it will not pose a weak point in the overall system. The overall cost efficiency of the joint design needs to consider not only the production costs but the entire lifecycle costs in terms of joint rehabilitation or sealing replacement, respectively.

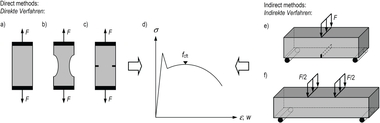

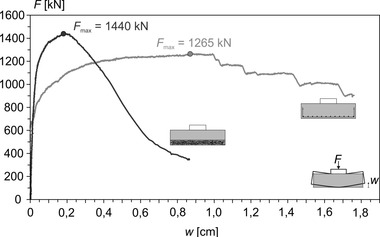

Within the scope of different research projects, structural systems from UHPFRC in precast design were developed for bridges and parking deck systems, and the design of various joint system options was examined on both a conceptual and experimental basis. To do so, basic concepts for different joining methods were developed and analyzed in a first step, one focus being on dry joints as well as poured joints with conventional reinforcement. Based on the test results, the structural behavior was analyzed in detail and described using mechanical models.

Co-authors: Prof. Dr.-Ing. Dipl.-Wirtsch.-Ing. Oliver Fischer, Nicholas Schramm