Zugspitze: Thermal anchor enables quick mountain hut construction

Also referred to as the “Top of Germany”, the 2,962 m high Zugspitze mountain is a popular tourist attraction that includes three glaciers, a breathtaking 360-degree panoramic view of Alpine peaks situated in four countries, and a large number of possible activities and restaurants. Each year, about 500,000 tourists from across the world use one of the three cable cars to access the highest peak of the country in a convenient way whereas 5,000 people climb it by foot. Those fond of mountain hiking traditionally use the Höllentalanger Hut as their accommodation.

In autumn 2013, this building originally constructed in 1893 was closed. Despite various extensions and conversions, it no longer met state-of-the-art requirements in terms of structural stability, fire safety and hygienic conditions. The first architectural competition for the design of its replacement was initiated as early as in 1997. However, the favored entry was ultimately rejected: according to experts, the pitched-roof design was not sufficiently resistant to avalanche impact, and could thus not be covered by insurance. In 2004, refurbishment of the existing building had been considered, but the related study arrived at the conclusion that only 5 % of the building footprint were suitable for long-term use. This is why a replacement was urgently needed. The related contract was awarded to Munich-based architect Stephan Zehl. His three-story, stepped building design covered by a monopitch roof borders on a slope and is perfectly protected against avalanches. Furthermore, this design made it possible to adjust the capacity of service rooms and sanitary facilities to current demand. The new mountain hut provides about 100 bedspaces and functional washrooms, drying rooms and rooms for keeping one’s shoes.

Quick, cost-efficient transport

When the old Höllentalanger Hut was put out of service in September 2013, preparations for the replacement building began simultaneously with the demolition of the old structure. Due to prevailing weather conditions, actual construction work commenced not earlier than in May 2014. In autumn and winter, all trails into the Höllental are blocked; the Alpine climate makes it impossible to carry out work for a period of eight months. These demanding conditions provided the backdrop against which the construction materials for the new building were chosen.

The rear wall of the building has a sophisticated structural design and borders directly on the mountain. Just like the retaining and transverse walls, it was built from reinforced concrete. For the semi-basement, core-insulated precast wall units were ordered from Fertigteilwerk Siegl. These elements were manufactured at the company’s production facility in Wörth by the Isar river; they exhibit a specially designed surface texture reminiscent of quarry stone that was created by inserted form liners. Their design specified by architect Stephan Zehl harmoniously integrates the hut with its mountainous surroundings. Timber was chosen for the remaining stories, which also enhances the natural appearance of the building.

“There are only hiking trails into the Höllental, but no road link. A helicopter had to be used to separately transport each and every piece onto the construction site, which is why speed and transport costs played a major role. Timber is an easy-to-transport, lightweight building material. The precast wall units were also very convenient in this respect because they enabled quick assembly – similar to a house of cards, but much more stable.”

Efficient heat insulation and safe and secure transport

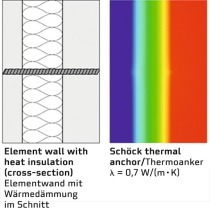

Compared to cast-in-place concrete, the precast wall units subsequently infilled with concrete ensured not only quick and easy construction and associated cost savings but also efficient heat insulation. Schöck thermal anchors acting as connectors and spacers were installed in these core-insulated precast walls. This anchor is made from glass-fiber-reinforced plastic; it minimizes thermal bridges and improves the heat insulation performance of the concrete walls.

Precast wall units were erected on-site and infilled with concrete. Since concrete expands and shrinks in the presence of extreme temperature fluctuations, the Schöck thermal anchor played a crucial role because, in mountainous regions covered with snow, the temperature difference between ambient air and wall surface may amount to up to 60 °C when the sun shines. Thanks to their low thermal conductivity and high tensile strength, Schöck thermal anchors protect the walls against cracking and damage.

Schöck worked together with Siegl to prepare all required designs and structural verifications for the double-wall units. Overall, eleven prefabricated concrete panels measuring 3.11 × 2.57 m were used in this project. “On average, each wall element includes 50 to 60 horizontally inserted Schöck thermal anchors and ten diagonal anchors,” explains Norbert Grupp, of the application technology department at Schöck in Baden-Baden. “To ensure structural stability of the precast wall units also during helicopter transport, the diagonal thermal anchor elements of the curtain façade were installed in a crosswise arrangement.”