The Mayan Train mega project thanks to the precast

The main target of the Mayan Train is to reduce the times and costs of transporting merchandise, passengers and tourists throughout the Yucatan Peninsula (Mexico). Approximately 1,525 km of railways will be built that will cross the states of Tabasco, Chiapas, Campeche, Yucatán and Quintana Roo, benefiting development in the region and the quality of life of the inhabitants. Of the 1,543 km, approximately 940 km correspond to newly built roads and 603 km to roads that will be rehabilitated. The Mayan Train will also have 59 stations, of which 40 will allow the transport of passengers and goods at different points along the route.

The consortium of companies led by Bombardier Transportation Mexico, was awarded the international public tender for the acquisition of the railway system made up of 42 trains and the electro-mechanical equipment. However, it is important to highlight that, for the development of one of the largest works in the Mexican history of rail transport, precast concrete technology is playing a fundamental role in terms of costs and punctuality in the delivery of the different sections of the railway. according to the work schedule.

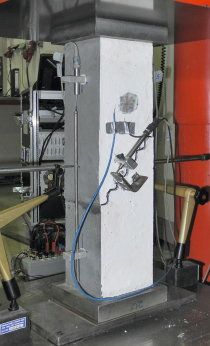

In fact, most of the infrastructure has precast elements such as sleepers, New Jersey type separators, cross drainage channels with square tubes and beams to build the viaducts. Considering the great distances between one station and another, different prefabricated plants were installed along the Mayan Train route, in order to reduce logistics costs and travel times between factories and work fronts.

Prefabricated concrete beams and sleepers

The first most important prefabricated plant built for this project belongs to the Civil Engineering Associates (ICA) consortium and is responsible for building the different concrete elements for the structure of the Mayan Train on section 4, from Izamal to Cancun. This factory is also in charge of building the New Jersey-type central barrier to divide the four lanes of the new 200-kilometer Mérida-Cancn highway, which runs parallel to the Mayan Train, in addition to the beams for the bridge structures that will be about 640 pieces. The central barrier manufacturing system will have 80 molds that are divided into eight 60-meter lines, which is equivalent to 160 pieces per shift. While the beams will serve for the construction of several vehicular bridges that will cross the highway.

In total for the Mayan Train, 24 viaducts will be built with prefabricated concrete beams whose total length is 6.8 km along the entire length of the train. The second largest factory is located in the town of El Triunfo, where 300 people work in three shifts of eight hours each to produce 1,800 sleepers per day. The process begins with the cleaning of the molds, the assembly successively goes to the stretching area, then to casting to be baked for 14 hours. The second prefabricated plant is located in the city of Umán, which has also already started production of sleepers with a capacity of 2,600 pieces per day and under rigorous quality tests. The third is in Calkiní (Campeche), where in this factory, in addition to the sleepers, the square tubes are made for the construction of the transversal drainage works (ODT) in the municipality of Poxilá, where this section will have 75 ODT. According to the last official bulletin, in general the progress of the Mayan Train work reached 40% at the end of June.

In section 1, the assembly of rails and sleepers is being carried out at the El Triunfo factory, in section 2, at the height of Uayamón, the construction and placement of various viaducts continue, with which the and will protect the ecosystem of this area. At the same time, the transversal drainage works are also advancing, to avoid possible flooding on the road during the seasonal rainy season.Finally, section 4 at the Piste junction, in Yucatan, continues the work of an important overpass for vehicles, necessary to guarantee the passage of the train according to the project.