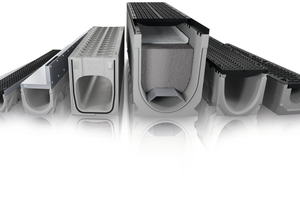

BG-Filcoten – more than just a concrete channel

With the BG-Filcoten drainage channels, BG-Graspointner sets a benchmark in terms of technology as well as in ecology and sustainability. The high-performance concrete developed internally meets highest technical requirements, while being a commitment to the ecology simultaneously.

Concrete is not simply concrete and everything getting in contact with soil demands highest standards on its environmental compatibility. In case of concrete channels, highest technical requirements as well as ecology and sustainability meet on equal terms. Apart from the costs, in particular sound knowledge about the material to be installed are of enormous importance, too, when it comes to the proper product selection. The intensive customer support that is required in this regard was an essential reason for BG-Graspointner to reorganize consultation and sales of their products. The new direct distribution in Germany creates even more customer proximity and allows fast and effective consultation at first hand.

Virtually a „mineral singularity“

The internally developed Filcoten HPC high-performance concrete is used for most of the projects at BG-Graspointner in the meantime. The brand name of the material describes the three main constituents: „Fil“ stands for filament (fiber), „co“ for concrete and „ten“ for tensile strength (bending tensile strength).

The development is based on specifications made by Friedrich Graspointner, who had already set the course 20 years ago: concrete remains the basic building material, no chemicals and plastics are to be used plus the development of a resource-conserving, sustainable and durable product. It is remarkable that in particular plastics are excluded, because other manufacturers frequently opt for polymer concrete, plastics or GRP for their channel systems. With Filcoten HPC, BG-Graspointner developed an innovative high-performance concrete that is mostly mineral.

A technical class of its own

Apart from the mineral composition, Filcoten HPC distinguishes itself by a particularly low w/c ratio as well as an extremely dense structure due to optimized aggregates. Together with the fiber modification to achieve an improved early-age cracking strength, the bending tensile strength could be tripled as against the 3.0 up to 4.0 N/mm² of „normal“ concrete. Even the compressive strength of more than 85 N/mm² is in a class of its own compared to usual values of conventional concretes. As far as the compressive strength is concerned, the requirements of EN 1433 are clearly exceeded. It is quite similar regarding the frost and de-icing salt resistance at a value of <25 g/m² W+R as against the required max. 1,500 g/m² W+R.

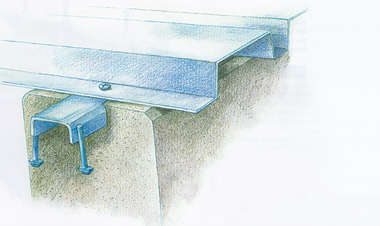

The load classes defined in EN 1433 are covered up to F900 depending on the product line without any problems. The values concerning the water absorption behavior are also lower than stipulated by the standard. As a result, Filcoten HPC complies with the exposure classes XC3, XD3, XF4 and XA1L required for the application of drainage channels. All in all, these properties lead to a very long service life of the BG-Filcoten channels.

Without competition in ecology and sustainability

A mineral composition is generally good for the environment; however, an ecologically flawless footprint requires even more. It was possible to save up to 70 % of the non-renewable aggregates sand and gravel in the development of Filcoten HPC, savings in cement amount up to 55 % – in comparison to a reference product made of conventional concrete. The production of cement is always related to a high CO2 emission. Hence, every reduction of the cement contents will benefit the environment. Significant energy-related savings were realized in the production of Filcoten HPC by using state-of-the-art manufacturing technologies. Moreover, 100 % of the energy demand at BG-Graspointner is covered by green electricity – with about 40 % coming from their own production. Only a few companies in the industry can prove such a sustainable energy footprint, according to the supplier. What is reason enough for the Upper Austrian energy savings association to award the company with the Energy Star 2021 for the engagement in terms of their operational energy transition.

With the reorganization of sales in Germany, BG-Graspointner actively sets the course for providing the customers, apart from mere product advice, also with information on the complex interrelation between ecology and sustainability in construction.

CONTACT

BG-Graspointner GmbH

Reinoldstr. 6b

50676 Cologne/Germany

+49 221 299 166-0