Carbon footprint, resource consumption, recycling – Slender, textile-reinforced precast concrete panels

If carbon-fiber and textile-reinforced concrete is promoted in the industry, the buzzword “sustainable” is generally mentioned at the same time. On the basis of the betoShell façade panel, a slender precast concrete panel, it will be transparently illustrated what leads to the implementation of sustainability as far as carbon-fiber and textile-reinforced concrete is concerned – however, which are current challenges, too. Therefore, it can be helpful to differentiate between the terms carbon footprint, resource consumption and recycling, which are often “measured by the same yardstick”.

Owing to the use of an optimized cement content and a low-carbon Portland limestone cement CEM II/A-L, the betoShell façade panel features reduced greenhouse gas emissions (carbon footprint) of just under 13 kg CO2-eq./m² relative to the raw materials used. In comparison to similar façade systems, it is demonstrated that the façade panel betoShell flex 30 is way ahead considered along the stages A1 (raw material supply), A2 (transport) and A3 (manufacturer).

This is partially due to the fact that resources such as aggregates can be reduced and that they are extracted from regional quarries for the most part, keeping transport emissions as low as possible. Electricity used in the production is generated in own PV systems, supplemented with 100 % green electricity in peak times only. A wood chip heater system is used for heating the production facility. Because of the customer-specific production of the panel sizes, there are hardly any production offcuts. Residual concrete is used to produce concrete blocks, and thus it is returned to further utilization.

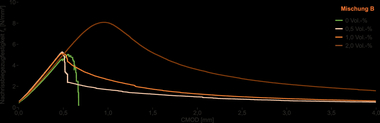

The recycling behavior, that has yet not been taken into account here, being probably different from those of steel-reinforced concrete, has been evaluated in a research project at RWTH Aachen. The application of glass-textile reinforcement proves to be advantageous in comparison to carbon-fiber fabrics here.