Suitability of recycled carbon fiber for use in fiber-reinforced concrete

This paper deals with the integration of recycled carbon fiber (rCF) into fiber-reinforced concrete to fully exploit its environmental and economic potential. Carbon fiber obtained from the waste of wind turbine rotor blades allows to close the material cycle while improving the mechanical properties of concrete.

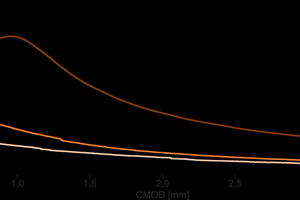

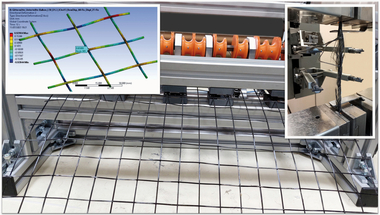

Concrete mixes with different proportions and lengths of recycled carbon fiber were assessed for its influence on compressive strength, flexural strength, and ductility. Results show that adding rCF significantly improves post-cracking behavior. More specifically, at a fiber ratio of 2% by volume, an increase in flexural strength by up to 60% was achieved compared to standard concrete. Longer, slender fibers proved to be particularly beneficial for post-cracking tensile strength and ductility, while shorter fibers promoted compressive strength.

However, it should be noted that a high fiber ratio adversely affects fresh concrete workability. This problem can be overcome by using suitable admixtures and optimized mixing techniques. Improved mechanical properties provide enormous potential for applications with demanding ductility requirements, such as structural components with increased susceptibility to cracking.

This paper also emphasizes the environmental and economic benefits of rCF. Compared to conventional materials such as steel, recycled carbon fiber is more cost-effective while contributing to the reduction of waste streams. However, it is necessary to conduct further research and revise relevant codes to standardize and mainstream the use of rCF in the construction industry.