Climate-friendly concretes and salt-frost scaling resistance – contradictory or not?

Against the backdrop of climate change, reducing carbon emissions

in cement and concrete production is one of the major challenges

in the construction industry. Beside process engineering

approaches such as the “Carbon Capture and Storage/Use” technology,

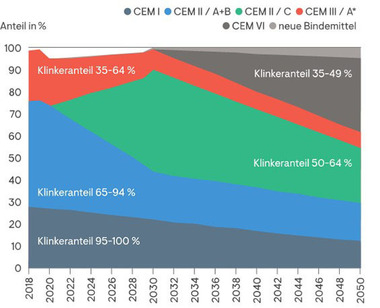

carbon emissions are reduced on the material side primarily by lowering the content of Portland cement clinker. However, such modifications must not impair the durability of the concrete. In this respect, the salt-frost scaling resistance is often a critical parameter. In order to enable the use of increasingly clinker-reduced cements (in accordance with the new DIN EN197-5 standard, for example) for different exposure classes, the previous approval procedure was adapted to better reflect practical concrete technology. In the new approach, cements with lower w/c ratios can also be approved (including three w/c ratio levels). However, cements must then also be used with these lower ratios. This new procedure will facilitate the launch of clinker-reduced systems particularly for concretes subjected to frost or salt-frost attack.

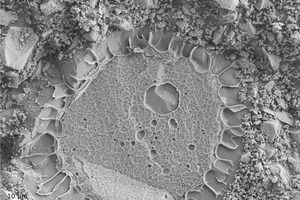

Besides this more generic approach of the approval procedure with respect to concrete technology, new types of chemical concrete admixtures can be used to make concretes low in clinker highly resistant to salt-frost attack. Novel air-entraining agents based on superabsorbent polymer (SAP) powders open up enormous potential in this field. These are plastics

that expand strongly in contact with aqueous

solutions, and form hydrogels. They will release the absorbed liquid again once cement hydration has reduced the moisture in the concrete and subsequently form an air void system that is exceedingly effective.

Unlike conventional air-entraining agents, SAP-based air-entraining agents can ensure a high salt-frost scaling resistance particularly in concretes with high clinker content.