Performance and durability of clinker-reduced concretes using specially designed additives

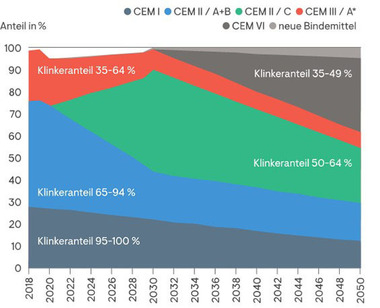

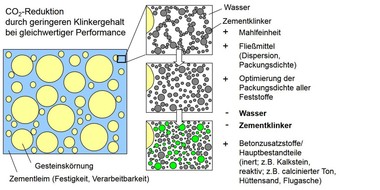

Following the announcement of global climate targets to reduce carbon emissions, clinker-reduced concretes (also known as eco-concretes) are becoming increasingly important in the construction industry. Such concretes stand out from their standard counterparts thanks to their improved carbon footprint, which can be optimized in different ways. Direct approaches include (I) the use of binders with reduced cement clinker content or the substitution of cement with additives and (II) the use of carbon-negative additives. Disadvantages associated with a reduction in cement clinker (in terms of durability and workability) can be offset indirectly by (III) optimizing

the packing density of the fine constituents or (IV) reducing the water/clinker ratio using superplasticizers.

From a concrete technology point of view, the practical applicability of the above approaches is limited in some cases owing to the availability of additives and the reduction in concrete workability and durability. However, large-scale application of eco-concretes requires their equivalence to standard concrete. A novel approach to eco-concrete production is to use special additives (hydration control agents, HCAs), which specifically intervene in the hydration

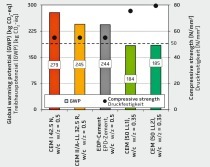

kinetics of the cement to exploit the potential of its structure-forming activity. In this context, extensive tests were conducted on different eco-concrete mix designs with added HCAs. References included concrete that used only Portland cement as its binder and eco-concrete mixes in which 50 % of the cement were substituted

with an additive (limestone powder, calcined clay, fly ash, or granulated blast-furnace slag). The results prove that, despite the enormous

reduction in clinker, the performance and durability of the tested concretes could, in some cases, be improved considerably compared to their references by adding HCAs.