ControCirc of the latest series for Harzer Betonwarenwerke

The Harzer Betonwarenwerke Company located in Goslar has a ControCirc milling machine, that Messmann had supplied in 1997, replaced by a ControCirc of the latest generation after almost 30 years. It is the third machine of this type for Messmann within 18 months.

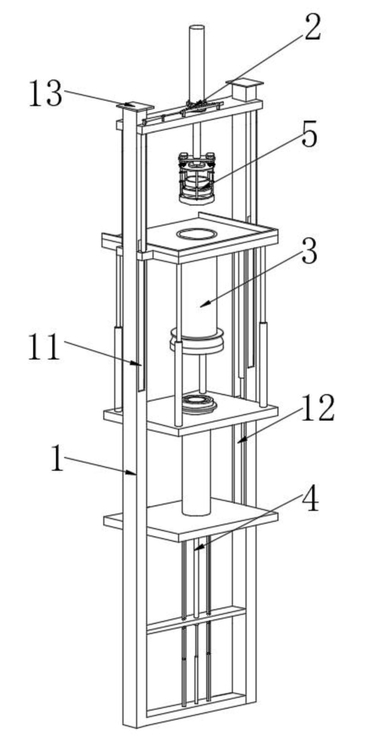

The machine is positioned between a pipe manipulator and a water-tightness testing device, with the pipes being manufactured without top pallets. The milling machine is centering on the center of the pipe, processes the spigot ends with a diamond milling cutter and ensures that the diameter of the pipe is correct. At the end of the processing cycle, a control measurement can be carried out, with exporting the results of the same to a USB stick.

Both Messmann and Harzer Betonwarenwerke are satisfied

The machine has – likewise the previous model – an additional milling tool for simultaneously deburring the front side of the pipe. The new machine type does no longer have a mandrel for movement of the axes. The positions are taken accurate to 0.1 mm by means of hydraulic cylinders via high-quality proportional valves and integrated measurement systems. This drive by means of cylinders will once more extend the service life of the machine in its aggressive and dirty environment.

Dipl.-Ing. Josef Messmann was obviously satisfied: „The replacement of the machines and commissioning only took some days. Gerhard Altmann, the plant manager of Harzer Betonwarenwerke, and his very qualified staff members were familiar with operating the new machine in next to no time. We assume that this customer will contact us again for a succeeding machine in approx. 2054.“