Cooperation based on trust for almost ten years

For several years, Glob-Metal has been managed by Konrad Zielaskiewicz, son of the company founder, who, together with his team, has been developing the company with the aim of improving logistics and technology.

The history of the family business

When the company founder, Krzysztof Zielaskiewicz, started his business in 1999, the precast concrete market was developing ever more rapidly each year. At the beginning, the work was done by ten welders. The company performed strongly over the following years so that, today, it employs a staff of 90 and its premises cover a total area of approx. 6 hectares.

In 2022, the company established an in-house record, producing and delivering approx. 600,000 reinforcement cages for L-shaped retaining wall panels to the customer. It has already invested in numerous technological solutions to automate production processes, and has continuously improved the quality of reinforcement. Additional investments are planned to drive further development.

Reinforcement cages made to measure

In the 1990s, most companies produced the reinforcement needed for formwork in-house, often in a manual process. When it became possible to obtain ready-made reinforcement from external sources, however, precast producers began to do some calculations. It was immediately clear that the in-house production of reinforcement for L-shaped retainingwall panels entails high costs for the company. It requires several workers with special qualifications, preparation work and equipment comprising suitable welding and steel-processing machinery. This takes up space on the production floor and produces large amounts of waste. It is also necessary to factor in the extremely high power consumption. It should be taken into account that this is not a continuous production process as is the case with professional manufacturers who can produce large batches of reinforcement cages on a daily basis.

All of the above-mentioned factors are associated with high costs and are inconvenient for the precast producer, who is faced with huge costs for the production of L-shaped concrete blocks as the finished product.

Trust comes first

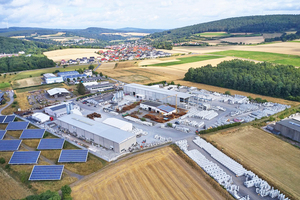

One of the numerous companies that have placed their trust in Glob-Metal for the supply of prefabricated reinforcement cages, looking back on a cooperation of almost ten years, is a leading manufacturer of precast L-shaped retaining walls based in the municipality of Bad Salzschlirf: Betonelemente Schmidt GmbH. The company has produced high-quality concrete elements since 1990 and is a valued supplier of small and large customers in the European construction market. When asked what prompted Betonelemente Schmidt to cooperate with Glob-Metal, operations manager Darius Chomiak explains: “As the person responsible for the continuity of production in the company, I choose a reliable supplier. Glob-Metal offers fast and just-in-time delivery of the quantities of reinforcement we need, which results in more space in our warehouse.”

Another element is the consistent quality of the Glob-Metal products. The company pays attention not only to welding seams and precise dimensions, but also to the quality of the steel used and to certification. And we are also convinced of this supplier’s professional customer service in terms of both logistics and technical matters, responding immediately by phone or e-mail.”

An offering as strong as steel

Customers often ask Glob-Metal how it is possible for the ordered reinforcement cages to be delivered within such a short period of time. From the moment the order is placed, the reinforcement cages are on site within just a few days. This is influenced by a number of factors. The main reasons are that Glob-Metal has specialized staff with many years of experience, an automated production process and extensive logistics. Cooperation with Glob-Metal also means that every customer is allotted the so-called quantity buffers of elements available in the storage location. “Just in time” is the guiding principle that Glob-Metal has consistently embodied for many years.

The reinforcement cages produced always comply with the manufacturer’s specifications or requirements. All changes are continuously incorporated into the production process. The technical staff constantly monitors the quality of production. Technical advice is also provided in many cases. It is appreciated that Glob-Metal is a highly flexible supplier that responds quickly and in a straightforward way to new customer requirements, such as an exchange of forms, or changes in the geometry or design of the L-shaped retaining wall panels.

The entire production process is constantly monitored and certified by an external testing institute in accordance with CE and DIBt (German Institute for Structural Engineering) regulations, which authorize the manufacturer to incorporate reinforcement in this type of wall panels. The reinforcement is properly packed on pallets and shipped to the recipient to ensure the lowest national delivery and transportation costs.

Glob-Metal supplies reinforcement cages for the full range of products to be manufactured, usually from 55 cm to 305 cm in height, in widths of 49 cm and 99 cm, as well as corner and special elements. Depending on the customer’s requirement, steel wire ropes, hooks, sleeves or other accessories can be attached to the reinforcement by welding.

CONTACT

Glob-Metal Konrad Zielaskiewicz

Przemysłowa 4

11-700 Mrągowo/Poland

+48 669 287 444

Betonelemente Schmidt GmbH

Karl-Post-Straße 1

36364 Bad Salzschlirf/Germany

+49 6648 9310-0