Long-standing experienced partner from Poland for

L-block reinforcements

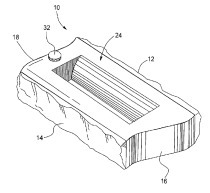

L-blocks are highly versatile and widely known concrete products used for earth retaining walls in road, railroad, industrial and housing construction. These uses include projects involving landscaping, embankments, parking lots, loading ramps and small-scale landscape architecture. They enable effective use for various types of modular standard and corner elements.

Built-in L-blocks are a successful combination of concrete and green-space elements – especially in urban areas where architects for developing green spaces combine aesthetics with functionality. This represents a very long-lasting solution, since the retaining walls are made of high-quality components produced under plant-controlled conditions. Installation of prefabricated walls at the site saves time and minimizes labor costs.

Built-in quality

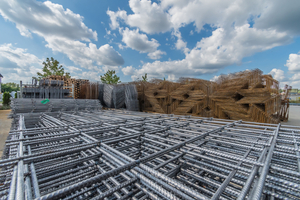

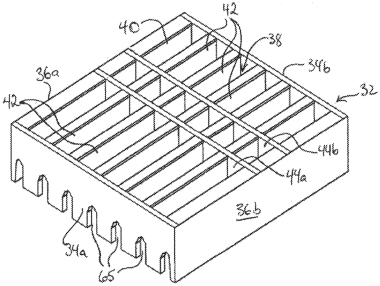

For a retaining wall to provide its greatest possible strength under full loading conditions, the reinforcement – i.e. its “backbone” – must be cast with concrete. “Our company has marketed special reinforcement cages of this kind for over 20 years. Over the years, we have become one of the leading manufacturers of welded reinforcement cages, of which we deliver around 600,000 annually to our customers. What sets us apart from our competition on the market is our very fast rate of order processing, constant contact with customers and the reproducibility of the products,” as Konrad Zielaskiewicz, the owner of Glob-Metal, explains. “Thanks to our modern machinery park, which minimizes error rates, we are able to satisfy even our most demanding customers.”

Just-in-time delivery

For companies that prefabricate L-blocks and with which Glob-Metal often collaborates, we can deliver the ordered reinforcement cages on the workday following receipt of an order. In such cases, clients need not maintain their own reinforcement stock – which requires additional space on the customer’s premises, as well as incurs additional costs.

Reinforcement cages are manufactured to the customer’s documentation. All possible changes and design modifications are continuously integrated into production. Our technical personnel continuously monitor product quality. In many cases, technical consultation is provided. Glob-Metal considers itself a highly flexible supplier that quickly reacts to customer’s requirements. Exchange of molds, change of geometries or of retaining-wall design, for example, is no problem.

Quality comes first

The entire production process is continuously monitored and certified by an accredited external testing institute and by the German technical approval body DIBt. The CE mark - that authorizes manufacturers of diaphragm walls to install the prefabricated reinforcement - is issued. Reinforcement cages are delivered on suitably packaged pallets to keep delivery and transport costs throughout Germany as low as possible.

Glob-Metal delivers reinforcement cages for all products that the customer can manufacture. They typically range from 55 cm to 505 cm, in height and in widths of 49 and 99 cm and as corner and special elements. Depending on the customer’s specifications, the element can be welded with ropes, hooks, sleeves or other accessories.

L-shaped retaining walls have become a new market trend in recent years. They are cast upside-down on a special form, with the foot facing upwards. The surface on both sides is of SB3 quality. In these cases, the reinforcement cages, due to the minimal concrete cover, require utmost precision.

Glob-Metal is a pioneer in this technology and has comprehensive experience. This type of reinforcement cages is manufactured with a tolerance of several millimeters, adjusted to the geometry of the formwork.

Reliable and trustworthy supplier

Glob-Metal has delivered complete reinforcement cages for L-retaining walls in Germany for many years. It has collaborated with many companies for decades and enables implementation of the most demanding investments.

Reinforcement cages from Glob-Metal are made completely of high-quality steel from prominent European steel plants. Spot welds and seams are subject to continuous quality control in every production phase. Each package of reinforcement cages that reaches the customer is provided with a CE mark to identify the product type before placing it in the formwork – as well as with a quality mark confirming that the products were manufactured in accordance with the relevant standards.

“What we like to emphasize is the fact is that we always place special attention on maintaining good business relations. We continuously develop our technological know-how and aim to further improve collaboration with existing and new customers,” says Konrad Zielaskiewicz.

CONTACT

Glob-Metal Konrad Zielaskiewicz

Przemysłowa 4

11-700 Mrągowo/Poland

+48 669 287 444