Difer Impianti becomes part of the mbk group

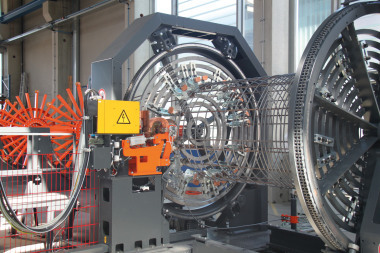

The mbk group is growing and integrating the Italian pile cage welding machine manufacturer Difer Impianti. Founded in 2007 by Leo Ferrari, the company specializes in the development and manufacture of its own piling machines. The machines on offer cover the entire range of sizes up to 3 m in diameter, including an extensive portfolio of accessories. mbk Maschinenbau develops and sells customized solutions for the concrete, construction and precast industries. The third-generation family-owned company has been active in the field of reinforcement welding machines for over sixty years and is one of the world‘s leading companies in the industry. Machines for processing reinforcing steel as well as customer-specific special machines round off the product range.

Difer Impianti and mbk are united by a very similar corporate philosophy of offering customers a high-quality, reliable and durable product. Combined with strong customer orientation and focus on after-sales service.

“After decades of dedication to the design and marketing of piling machines that have improved the production of foundation piles around the world, the time has come for me to retire. It is with great pleasure that I have sold my company Difer Impianti to Mario Pfender of mbk, safe in the knowledge that he will be able to continue it with great success,” says Leo Ferrari.

Challenges and opportunities

Mario Pfender, Managing Partner at mbk comments: “I am looking forward to the new challenge and the opportunities we have together. The Difer gas shielded arc welding machines complement mbk‘s resistance welding machines perfectly. Together we are able to cover almost all requirements in the field of cage welding machines for bored pile cages. With the gas-shielded arc welding machines, the resistance welding machines and the patented Dual Weld Option (which combines both technologies in one machine), we offer a range that no other supplier can match.”

Both companies benefit from their respective experience in this segment and want to utilize synergies in the future, not only in the areas of sales and service. Stefano Gabrielli, Technical Director at Difer Impianti, adds: “After 20 years of experience in the reinforced steel machinery sector, particularly with the pile cage machines, I’m thrilled to embark in this new chapter with MBK and our new CEO, Mario Pfender. This is a huge opportunity for both Difer Impianti and myself, and I can’t wait to see how we can further strengthen our company for the future. The journey continues, and I’m excited for what lies ahead!”

CONTACT

mbk Maschinenbau GmbH

Friedrich-List-Str. 19

88353 Kisslegg/Germany

+49 7563 9131-0