Digitalization in the precast plant using UniCAM.23

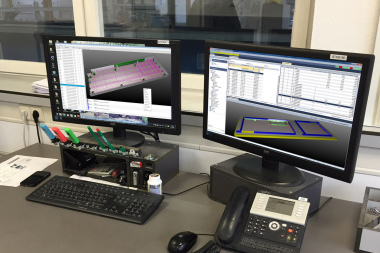

Unitechnik is setting new benchmarks in the precast concrete industry at Bauma 2022, according to the supplier: With UniCAM.23 the provider of industrial automation based in Wiehl will present the latest version of its production control computer. The new solution clearly stands out from the predecessor UniCAM.10 by a modernized appearance and many new functions. In addition to improving paperless manufacturing and cycle time homogenization, the main focus is on a new software structure with several dashboards. They will help increase the performance and availability of the plant.

New production control computer to be presented at Bauma

According to the motto „added value from data“ Unitech supports companies in the precast concrete industry in optimizing the processes with the aid of UniCAM.23. Intelligent, partially AI-based algorithms analyze existing information. Visualization on the dashboard allows for answering various questions and thus increasing the availability and performance of the plant. Maintenance staff, for example, can identify and eliminate weak points in the plant by means of a systematic evaluation of fault messages.

Eliminating faults before concrete placement

Apart from a well-functioning process, control and documentation are important elements of quality management. The function „element check pro“ displays the worker an exact and true-to-scale photo of the pallet, which he can overlay with CAD data. The individual levels of the element data such as „reinforcement“ and „mounting parts“ can be shown and hidden here. It is also easy to identify and correct deviations in the position and the completeness of the components. Any deliberate deviations are documented with comments and filed together with an image. For this purpose, the staff insert comments at any position in the photo.

After the removal of the elements, UniCAM.23 offers a similar procedure. Following the final physical inspection, it is possible to attach comments to the graphic image of an element. If then the construction site has a complaint, all it takes is a few clicks in UniCAM.23 to view the entire history of the element.

Inventory management made easy

Another new feature is the „easy storage“ function. Under this name, the inventory management already implemented on a custom-specific basis becomes an integral part of UniCAM.23. The function allows the individual creation of an outdoor storage topology. Elements are stored on a free place and are booked to the storage location by means of a fork-lift terminal. Afterwards, they are retrievable by the order number. The customers, who want to load their outdoor storage area by means of a gantry crane, are provided with another advantage.

Unitechnik enables retrofits independent of the manufacturer

With UniCAM.23 embedded, it will be possible in future to provide the functions of UniCAM.23 on third-party host computers too – on the Beckhoff PC of the shuttering robot control system and as a mini PC in the control cabinet, for example. This innovation allows a large number of retrofit scenarios and provides plant operators with the option of combining systems of different manufacturers.

With UniCAM.23, Unitechnik Systems brings a software to the market that can be operated more intuitively and used more flexibly. The software structure meets the highest demands on IT security and offers the latest platform technology. The continuous further development of the solution is oriented on the requirements of the operational practice and is aiming at increasing the productivity and quality of the precast concrete plant. In the future, it will be possible to retrofit the latest functions more easily. Unitechnik will present UniCAM.23 from October 24 to 30 at Bauma 2022 in hall B1 at booth 151 – directly at entrance west.

CONTACT

Unitechnik Systems GmbH

Fritz-Kotz-Str. 14

51674 Wiehl/Germany

Wolfgang Cieplik

+49 2261 987-208