Eco-balance of reinforced-concrete constructions: comparative study of prestressed- and semi-precast floor slabs

Precast prestressed-concrete floor slabs are characterized by long spans, low reinforcement ratios and lightweight, material-saving construction methods. What eco-balance do they offer in comparison to conventional structures?

Until now, there has been little consideration of the potential savings enabled by loadbearing structures in terms of resource consumption and CO2 emissions. A current study shows the potential that can be exploited here. This study focusses on the question of how various loadbearing floor systems affect the eco-balance of a building, and on which opportunities material-saving prestressed-concrete floor constructions offer.

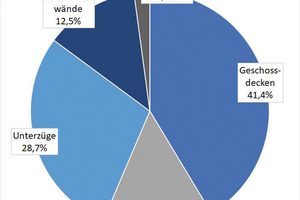

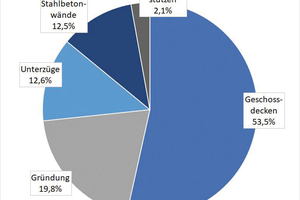

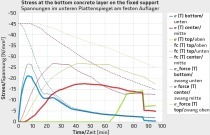

The Berlin University of Applied Sciences (HTW), headed by Prof. Dr.-Ing. Andreas Heuer, investigated, for the first time and by a comparative eco-balance –on behalf of the German Federal Association for Precast Prestressed Concrete Floor Slabs – an entire loadbearing structure, from the floors to joists and columns down to the foundations. In the study, three structurally identical residential buildings, erected in 2018-2019 with prestressed-concrete floor slabs, were compared with a conventional construction erected with semi-precast floor slabs. The buildings were a residential complex for students, built as a slim-floor structure consisting of precast prestressed-concrete floor slabs and flush composite columns.

The study clearly reveals that the use of slim floor structures consisting of precast prestressed concrete floor slabs enables savings of enormous quantities of raw materials, and appreciable reduction in greenhouse gas emissions.

In addition, this presentation discusses future developments that result from the DAfStb-Code of Practice entitles “Greenhouse gas reduced structures made of concrete, reinforced concrete or prestressed concrete”. The presentation offers initial results in this context.