Electrically conductive carbon reinforcement

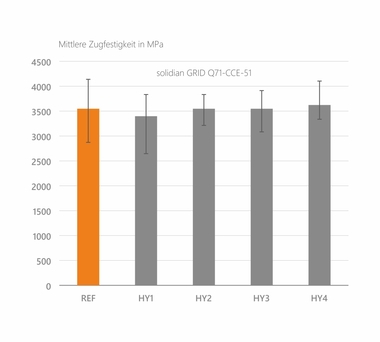

Reinforcements made of carbon fibers are usually impregnated with a polymer that has an insulating effect. Accordingly, they do not conduct electric current. Solidian, the specialist in non-metallic reinforcement, is now launching its Solidian eGrid, a carbon reinforcement that can do just that. The advantage: the reinforcement is now able to take on additional tasks that hardly anyone had thought of before.

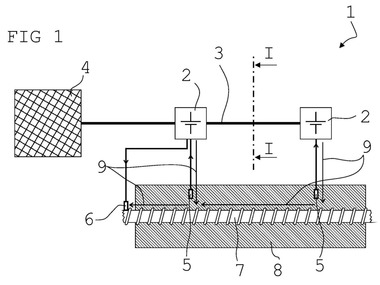

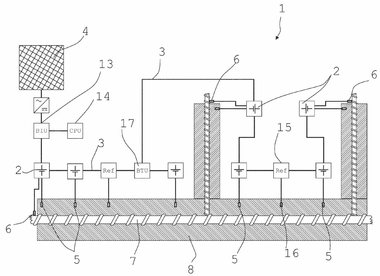

For example, the conductive carbon reinforcement can be used to heat concrete surfaces and thus de-ice runways or loading ramps. And when used as cathodic corrosion protection, it prevents the corrosion of steel reinforcement. In this way, it can completely replace the very expensive titanium nets or strips previously used. In addition, carbon reinforcement can be used for extended functions such as simultaneous reinforcement of the structure. If not one but two layers of Solidian eGrid are installed, the penetration of moisture into the concrete can additionally be monitored. Between them, the electrolyte resistance of the concrete is measured, indicating any increase in moisture. To make this application as simple as possible, the manufacturer offers an appropriately prefabricated system consisting of two layers of reinforcement and the necessary spacers.

Preventive cathodic corrosion protection

Reinforcing steel is usually covered with a thick alkaline concrete layer. This ensures that a protective passive layer is formed on the steel. However, CO2 can cause the pH of the concrete to drop and the passive layer to shrink. Penetrating chlorides (road salts) can also lead to the same result. The result is steel corrosion. The reason: at the unprotected site, the steel becomes the anode, the protected site becomes the cathode, and the effect of a galvanic cell (battery) is created. This results in a slight flow of current, which gradually erodes the unprotected steel. This process can be suppressed by current introduced from the outside, which is called cathodic corrosion protection.

In preventive cathodic corrosion protection, the current is introduced when the pH value is not yet in the critical range or when the chlorides have not yet penetrated to the load-bearing reinforcement. This prolongs the service life of the reinforced concrete and any repairs that may be necessary can be postponed to a later or more favorable point in time.

Text: Dipl.-Ing. Claudia El-Ahwany

CONTACT

Solidian GmbH

Sigmaringer Straße 150

72458 Albstadt/Germany

+49 7431 10-3135