Excellent collaboration of all parties involved in the modernization of Lintel’s concrete plant

A new production facility, supplied and installed by Topwerk company Hess Group, has been in operation at the Porta Westfalica concrete plant of Betonwerk Lintel GmbH & Co. KG since the beginning of June. Its core component is an RH 2000-4MVA concrete block machine, which is the second plant supplied to Lintel by Hess.

With locations in Rheda-Wiedenbrück, Porta Westfalica, Lemgo, Paderborn and Brilon, Betonwerk Lintel GmbH & Co. KG operates five production sites in northwest Germany. The Group is completed by Vogt Bautechnik GmbH. It has a total workforce of around 180, of which 28 are currently employed at the Porta Westfalica plant.

Comprehensive product portfolio and commitment to sustainability

Founded in Rheda-Wiedenbrück in 1982, Paderborn and Brilon were taken over in 1997, Porta Westfalica and Lemgo in 2001. All four locations were integrated into the Group. The full merger of all plants into a single company was completed in 2020. Municipal road construction is currently the main pillar of the Lintel Group’s business activities. As itemizing the complete product portfolio alone would fill this article, suffice it to briefly name the main groups: VisioClean range (concrete blocks with superhydrophilic surface), creative pavements, ecological pavements, concrete slabs and ceramic tiles, a variety of design elements, and the special Conguardia surface finish.

The Lintel Group also sees itself on the right track in terms of ecological considerations and sustainability. Rejects and residues from production are now processed at the plants and fully returned into the production process – there is therefore no longer any concrete waste to be disposed of. Production facilities optimized in terms of energy efficiency minimize energy consumption; the increasing use of electrically powered means of transport in the factories is continuously improving the energy footprint. The company also operates solar systems for internal consumption installed on the factory buildings. Additional special solutions, for example, in the area of climate resilience, are currently under development.

Start of a new production facility in Porta Westfalica

A new production facility, supplied and installed by Topwerk company Hess Group, has been in operation at the Porta Westfalica concrete plant of Betonwerk Lintel GmbH & Co. KG since the beginning of June. Its core component is an RH 2000-4MVA concrete block machine, which is the second plant supplied to Lintel by Hess.

Lintel’s managing director, Thomas Theilmeier, emphasizes the excellent collaboration between all parties involved: “Our biggest challenge – integration into the existing factory concept – was overcome in a highly positive and constructive process. After all, we are talking about a total investment of several million euros. Therefore, I would like to once again say a big thank you to all project partners – we’d always do it again!”

Lintel intended to replace the two existing block machines with a new high-performance plant. The existing mixing plant was to be modified and used to supply concrete to the new plant; another existing building, which is currently used for product finishing, was to be connected and integrated into the plant concept.

The following production equipment was supplied and installed by Hess:

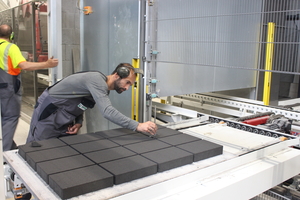

RH 2000-4 MVA concrete block machine in high-performance, ultra heavy-duty design

High-performance control system for fast, precise, and gentle motion sequences

Automatic quick-change system for molds: the currently installed mold is released and ejected below the face mix unit; the new mold is simultaneously fed to the machine below the core concrete unit and clamped. This saves time, is carried out conveniently by a single employee using a mobile panel, and significantly reduces the risk of injury.

4 tamper head cylinders for maximum accuracy of the block height,

Colormix system for the face mix unit,

Movable core and face mix unit for easy access and easier cleaning.

Other major features include: lasers for measuring the block height, separator unit for additional product checks, double washout unit, elevator / finger car / lowerator with 28 levels, one each block remover and doubling unit, grouping unit, one each fully electric cubing system with servo motor and board package mover.

This is complemented by a second dry side to allow the automatic integration of a finishing system, cubing with cover sheet dispenser, horizontal and vertical strapping, strip inserter and surface protection with waterproofing device.

Two planetary mixers from Pemat

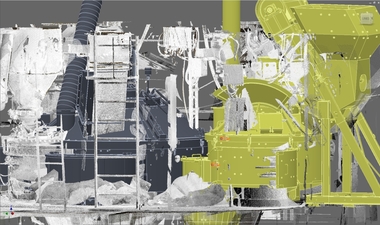

Besides the concrete block machine from Hess, the mixing plant is one of the highlights of the new production equipment.

Pemat Mischtechnik GmbH supplied two mixers for the plant: the core concrete is produced with a PMPR 2250 planetary mixer with an input of 2,250 l and an output of 1,500 l. The face mix is produced with a PMPM Multimix 750 planetary mixer with an input of 750 l and an output of 500 l. The PMPM Multimix with additional, independently controlled whirler offers a number of advantages:

excellent distribution of the mix even when using fine-grained materials,

ultra-fast homogenization,

maximum possible repeatability,

very high energy efficiency,

high-precision gearbox,

independent rotor,

interval-controlled change of the direction of rotation,

gearbox design by SEW Engineering,

service life exceeding 10,000 hours,

patent protection.

Both mixers are loaded as follows:

Aggregates: both mixers with on-site reversing conveyor,

Cement: both mixers with one each on-site cement-weighing unit.

PMPR 2,250 with an existing cement-weighing unit.

PMPM 750 and back-up with an existing cement-weighing unit with reversible auger.

Admixtures: from on-site IBC containers.

Color in the face mix: with existing Remei/BPB doing system.

The fresh concrete is fed to the bucket conveyor on site by means of a belt conveyor.

Other partners contributed to success

According to Lintel’s managing director, Thomas Theilmeier, this success story would not have been possible without the other partners and suppliers involved, who are therefore acknowledged below.

The curing chamber (year of manufacture 2022/23) was supplied by Kraft Curing Systems GmbH. It comprises 16 aisles with 12 spaces per aisle on 28 levels. When asked by the BFT editorial team, managing director Michael Kraft stated that the company now holds a patent on the Kraft rack design.

Other partners included Beckhoff, Gierecker & Bröckelmann, ZP Planungsgesellschaft, and Wegener Brandschutz. Theilmeier also acknowledged Lintel’s dedicated engineering department – the bucket conveyor system, for example, was built in-house. Other production equipment at Lintel’s Porta Westfalica plant (some in inventory) was supplied by VHV (double belt conveyor), Probst (forklift clamp attachment), Remei BPB (concrete chemicals), Qavertec, HIT (board crane), Baumhus Stahlbau (hall) and Horstmann + Freise (dosing system).

CONTACT

Betonwerk Lintel GmbH & Co. KG

Kapellenstraße 1

33378 Rheda-Wiedenbrück/Germany

+49 5242 9283-0

Hess Group

Freier-Grund-Str. 123

57299 Burbach/Germany

+49 2736 4976-6689

Pemat Mischtechnik GmbH

Hauptstraße 29

67361 Freisbach/Germany

+49 6344-9449-0

Kraft Curing Systems GmbH

Muehlenberg 2

49699 Lindern/Germany

+49 5957 96120