Extension of the design rules for RAC for resource-efficient construction of the future

In view of the elevated level of carbon emissions and scarcity of natural resources, new concrete mix designs are constantly being tested to meet the increased requirements for resource-efficient and climate-friendly construction. Using recycled aggregates from processed demolition waste in so-called recycled aggregate concrete (RAC) is an effective measure to save natural resources (Fig. 1). In Germany, a guideline issued by the German Committee for Structural Concrete (DAfStb) governs the use of coarse recycled aggregates of type 1 (≥ 90% by volume of concrete rubble) and type 2 (≥ 70% by volume of concrete rubble) in structural concrete up to strength class C30/37. These rules will be extended upon the introduction of DIN 1045‑2:2023. Depending on the substitution rate αRA, this standard differentiates between concrete classes BK‑N, BK‑E, and BK‑S for normal, increased, and special requirements.

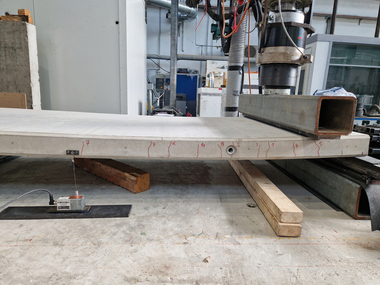

In a current research project, the Institute of Structural Concrete (IMB) at RWTH Aachen University joined forces with the Department of Construction Material Technology at RPTU Kaiserslautern-Landau to conduct theoretical and experimental investigations to extend the application limits of RAC in class BK‑E. The main goal is to extend the applicability of RAC up to strength class C50/60 and to use fine RA of type 2. At the same time, clinker-efficient cements are used to reduce the carbon footprint, besides saving natural resources. The IMB focuses on investigating the bond and shear behavior of RAC members. Conducting systematic experimental investigations and creating and evaluating databases on the bond and shear behavior of RAC components should allow for the existing design rules to be reviewed and refined also with regard to the next generation of Eurocode 2.