Low-carbon, resource-efficient concrete for precast elements – Workability and early strength

There are many ways to achieve the required significant reduction in carbon emissions and resource efficiency in concrete production and processing. Using clinker-efficient cements, such as CEM II/C-M or CEM VI, is a promising, easy-to-implement mitigation

measure. In hardened state, any concrete so designed will generally exhibit high performance characteristics while being suitable for many applications in standard exposure classes. However, such types of concrete have previously been associated with economic limitations

for the precast and concrete products industries owing to a greatly

reduced binder and clinker content, the associated limitations in workability, and the slower development of strength.

The challenges for developing such low-clinker, resource-efficient types of concrete that arise in terms of their workability, early strength, and durability constitute a multi-parameter problem. A combined approach is necessary when considering the binder composition and ratio, the granulometric characteristics of the aggregates – particularly of the fine fraction –, the targeted use of chemical admixtures, and the interactions between the individual components.

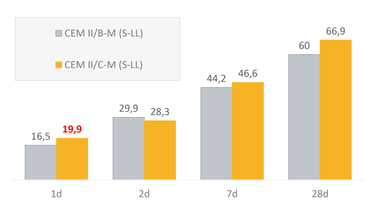

Systematic investigations showed that optimizing the packing density of the fine aggregate particles and of the binder by adding early strength-enhancing admixtures makes it possible to achieve the workability and lifting strength levels required for precast elements and concrete products even with very low clinker ratios ranging from 30 to 40 % by mass. In addition to the technical characteristics referred to above, this would also allow for a significant improvement of the carbon footprint and resource efficiency of concretes produced in this way.