From the coil to the finished product bundle

At the forthcoming bauma, which will take place from October 24th to 30th in Munich, Eurobend will be showing the latest generation of welding machines for wall reinforcement and wall ties in Hall C3, Stand 225: the PLT Ladder and PLR Truss series.

A lack of skilled workers, limited production and storage space, increasing material costs, the need for high flexibility and just-in-time production (JIT) are some of the challenges the construction industry is currently confronted with. Eurobend offers the right solutions with innovative concepts and the use of state-of-the-art technology.

The PLT Ladder and PLR Truss series are equipped with flexible stacking and bundling stations. The bundles produced are strapped fully automatically without interrupting production and transferred to a buffer table. The operator is only responsible for coil loading and removing the strapped bundles from the buffer table. He works very comfortably in an attractive workplace.

Eurobends answer to the challenges of our time

Switching to a new product type is very easy and only takes a few minutes. The machines offer maximum flexibility in production, which significantly reduces the space required for storing the different types of products. Customers can produce just-in-time and only produce “exotic” product types when they are asked for.

The connection to the IT systems of the company always gives the production planners the current picture in the production hall and facilitates order planning and material orders.

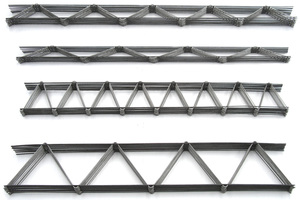

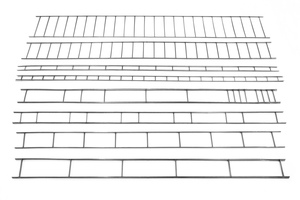

Both series offer machines performing overlap welds (the PLR models) and also so-called “T” welds (butt welds) (the PLT models), the latter with significant material savings reducing costs.

Due to the compact design, the machines require little space. Maintenance is easy thanks to the thoughtful design and easily accessible components.

CONTACT

Eurobend GmbH

Alexanderstr. 1

90547 Stein-Nuremberg/Germany

+49 911 9498980