Future prospects in cement technology:

What lies ahead?

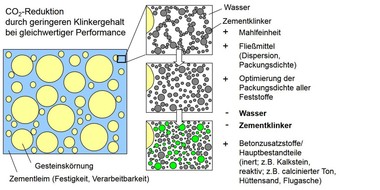

Around 80 % of the CO2 footprint in concrete production results from cement production. Production of cement clinker, in particular, results in high specific CO2 emissions of 800 kg/t on the average. Biogenic fuels can reduce fuel-related emissions and thus a proportion of total emissions. Future plans call for separation of unavoidable CO2 by carbon-capture processes such as oxyfuel technology. Until then, the greatest lever for CO2 reduction is by reducing the clinker content in cement and by use of supplementary cementitious materials (SCM), such as granulated blast-furnace slag, fuel ash and limestone flour. CEM II/C and CEM III cements are suitable for all exposure classes (some cements are excluded from exposure classes XF2-4) and have good processing properties.

Today, cements with high clinker content, and up to Portland cement (CEM), are still in use in precast element production. The reason for this is the required high early strength of the construction elements made with them. These elements must be capable of being quickly demolded to ensure high production output. Special blast-furnace cements (CEM III/A 52,5) can, if activated, develop the same early strength as Portland cements of the same strength class. Initial practical experience shows that CO2 reduction of about 50 % can be achieved. Furthermore, the chemical resistance of concrete can be increased with these cements.

Over the long term, the availability of blast-furnace slag and fly ash will decrease. Natural pozzolans and calcinated clays can also be used as SCM. Especially great savings in CO2 can be achieved with mechano-chemically activated clays. Initial results show that cements of this kind exhibit long-term durability.