Market trends for green cements for environmentally friendly concretes (Part 1)

Green cements are booming because the cement and concrete industry is on a net-zero journey to become carbon-neutral by 2050. What are the latest market trends for green cements and which types of green cement will have a major impact? Some answers will be given in Part 1 of this article.

Green cements are booming because the cement and concrete industry is on a net-zero journey to become carbon-neutral by 2050. But what contribution can green cements provide to reduce carbon emissions in the cement industry? What are the latest market trends for green cements and which types of green cement will have a major impact? Some answers will be given in Part 1 of this article.

1 Introduction

Buildings account for an estimated 37% of the global carbon emissions. About one third is generated during the construction phase, while two thirds are generated during the lifetime of the buildings and the corresponding energy consumption. The use of concrete and mortars, both of which are produced using cement, is indispensable in construction. If 25% of cementitious products were replaced by timber, this would require planting and harvesting a forest 1.5 times the size of India. But in real terms, as a result of deforestation and fires, forest loss has become a problem on all continents (Figure 1).

So, what other solutions will work if there are no alternatives to cement and concrete? The answer is low carbon cements or “green cements”. Alfacem (Figure 2), EcoCem, EcoPlanet, Ekkomaxx, FutureCem, Geopolymer cement and LC3 are examples of green cements. However, some of them are no more than a new name for cement or concrete additives that were previously known as fly ash and slag cements or concrete additives.

2 Green cement challenges

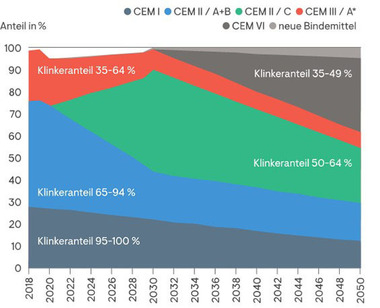

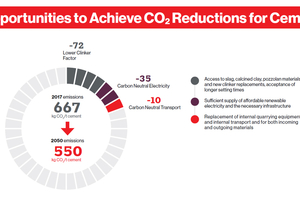

Green cements are booming because the cement industry is on a net-zero journey to become carbon-neutral by 2050. Figure 3 shows how green cements can contribute to the net-zero journey. The figures have been provided by CEMBUREAU, the European Cement Association. According to these figures, another 72 kg/CO2 can be avoided by further reducing the clinker factor, which is about 10.8% of the 667 kg CO2/t cement emissions, based on the output in 2017 [1]. So we are only speaking about 10% to 11% of future CO2 reduction. In 2017, the clinker-to-cement ratio (clinker factor) in Europe was 77%.CEMBUREAU has renewed its ambition to move from that level to 74% by 2030 and to 65% by 2050. This will be achieved by new types of cement as well as by traditional clinker substitutes such as fly ash, granulated blast furnace slag and non-traditional clinker substitutes such as calcined clay.

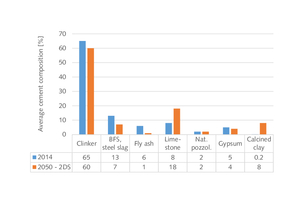

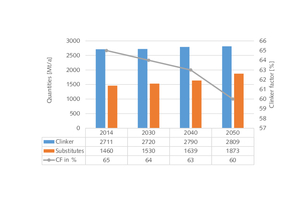

A forecast by the IEA [2] dating from 2018 is often used to calculate the future amount of green cements and clinker substitutes. Figure 4 shows the global average composition estimates for cement in 2014 and 2050. According to the IEA, the clinker factor will decrease from 65% to 60%, while granulated slag and fly ash will significantly decrease, and limestone and calcined clay will increase. The matter gets really interesting when taking into account the cement production levels predicted by the IEA (Figure 5). According to the IEA forecast, the global cement production will grow steadily from 4171 million annual tons (Mt/a) in 2014 to 4682 Mt/a by 2050. With a clinker factor of 60% by 2050, about 1873 Mt/a will be non-clinker cement components, with about 375 Mt/a made up by calcined clay alone. However, much of this data is questionable, such as the amount of granulated blast furnace slag (GBFS) and other metallurgical slags in the cement composition.

Another challenge is the declining availability of GBFS, fly ash and other natural pozzolans. According to a OneStone report [3], the production of GBFS in Europe will decrease from 24.7 Mt/a in 2021 to 21.5 Mt/a by 2030, which is a decline by 13%. In Western Europe alone, the GBFS trade balance will become negative, and to meet the requirements of the cement and concrete industries, about 6.5 Mt/a of GBFS will have to be imported in 2030. In other regions, especially in Asia, the production of GBFS will significantly increase up to 2030. According to our forecast, the global GBFS production will increase from 331.3 Mt/a in 2021 to 381.0 Mt/a in 2025 and 416.6 Mt/a by 2030. China will have the largest growth, but GBFS production will also grow in the rest of the world due to increasing slag rates and additional BFS granulation plants. At the moment, it is very difficult to predict the situation up to 2050, but the IEA forecast assumption of only 1% of GFBS in the cement mix 2DC and the transition of the steel industry to carbon neutrality is more than questionable from today’s viewpoint.

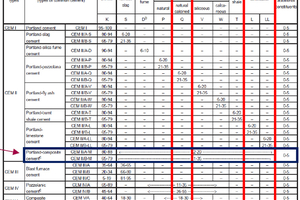

The next challenge is the adaption of cement standards. Let us just consider the example of calcined clays and LC3 cements and the European cement standards. Limestone-calcined clay cement is allowed in the European cement standard EN 197-1 as CEM II/A-M and CEM II/B-M (Figure 6). However, the minimum clinker content has to be 65%, and limestone + calcined clay can only be in a range of 12% to35%. LC3 cements have been proven to have a similar quality to standard Portland cement, but they are composed of 50% clinker, 35% calcined clay, 15% limestone and 5% gypsum. Accordingly, the full potential in CO2 reduction is not possible with the EN 197-1 standard. The industry pins its hopes on the new EN 197-5, which focuses on ternary cements and allows new types of CEM II/C-M and CEM VI. It has to be noted, however, that in EN 197-1, CEM III/C cements already allow a clinker content of only 5% to 19%, while 81% to 95% of GBFS are allowed.

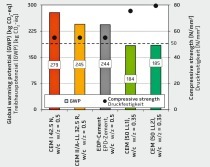

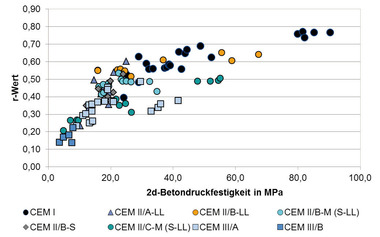

The new EN 197-5 standard is the result of many years of research focusing specifically on the durability of low-clinker concretes (Figure 7 and Figure 8) [4]. The idea behind it is to grind the clinker component more finely and combine it with a cementitious component and limestone. Compared to CEM I Portland cement with a clinker content of 95%, the CEM II/C-M and CEM VI cements covered by EN 197-5 will enable the wider use of low-clinker cements towards the goal of carbon neutrality in concrete construction. For CEM II/C-M Portland composite cements, the clinker content can be reduced to 50% by mass and for composite cements in the CEM VI group to 35% by mass. EN 197-5:2021 has already been implemented by a number of European countries but there are also countries that will need more time to adapt.

3 Green cement developments

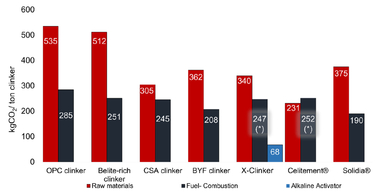

Many new cements and alternative clinker technologies (ACT) have been developed over the years [5, 6], but at this time it is still difficult to say which ACTs will have the largest impact as an alternative to OPC clinker. The main options under review are: Belite-rich clinker, CSA clinker, BYF clinker, X clinker and Celitement. Reactive belite cement contains the same four cementitious phases (alite, belite, tricalcium aluminate, and tetracalcium aluminoferrite) as Portland cement, but in different proportions. With lower sintering temperatures of 1250°C instead of 1450°C, higher belite and lower alite phases are produced, and carbon formation is reduced accordingly. CSA (calcium sulphoaluminate) clinker also uses temperatures of 1250°C. CSA cements were developed in the 1970s to compensate the lower early strengths observed in belite-rich cements. Typical raw materials used in the production of CSACs are limestone, calcium sulfate and aluminum-rich minerals or industrial by-products.

BYF (Belite-ye’elimite-ferrite) clinker can also be produced at temperatures of 1250°C but at lower costs than CSA clinker because the relatively expensive aluminum-rich raw materials can be reduced, resulting in a higher proportion of silicate and ferrite phases. X-clinker is a development by Cimpor and Tecnico in Portugal. The production process allows the use of traditional raw materials, such as limestone, clay, marl and sand by melting the raw mixture at a temperature of 1550°C. However, because much less limestone is used, the process has a 25% smaller carbon footprint than the one for standard clinker. Celitement takes an entirely different route. The technology, which has been acquired by Schwenk Zement in Germany, principally uses CaO, SiO2 and water as raw materials. The production process comprises two main steps: an autoclave produces a non-reactive CSH intermediate product in a first step, and the autoclaved intermediate is transformed into the final reactive product in a special grinding step.

Figure 9 shows a simplified schematic representation of the stages considered in the production processes of the ACTs under review [6]. The comparison also includes the standard OPC production process for reference purposes and the Solidia cement approach. Solidia is a non-hydraulic binder produced using the same raw materials as OPC, but with a lower amount of CaCO3 and a kiln temperature of around 1200°C. According to the figure, Solidia has an overall C/S molar ratio of around 1, but it needs to be cured by exposing the concrete mix to a high-concentration gaseous CO2 environment of 60% to 90%. It has to be noted, however, that only Celitement and X-clinker presently consider a scenario of full process electrification, while the other solutions follow a concept based on fuel combustion, similar to the existing clinker production processes.

REFERENCES/LITERATURE

![Fig. 09: ACT production processes [5]](https://www.bft-international.com/imgs/2/0/2/7/5/1/5/tok_cfe2085f3db3f66f3785fb6123800186/w300_h200_x600_y379_HA_1221_Fig.09_Fig9L_ACT1-5de692a5d00ad59c.jpeg)