Green, digital,

resilient - Precast Concrete Solutions

Construction’s future in the context of a green and digital society (Philip Crampton)

The transition of our societies and economies to climate-neutral and digital societies is one of the biggest challenges of our time. Both transitions have become top priorities in recent years for us, our member federations, and our companies.

The drastic effects of climate change and of global warming are becoming more and more visible and are increasingly being felt by our societies – also in Europe. Our sector has a special role to play in the green transition: We are one of Europe’s largest industrial sectors - we make up 11.1% of the EU’s GDP, 29.8% of industrial employment, and 6,6% of the EU’s total employment.

In the EU, buildings are responsible for about 40% of the EU’s total energy consumption and for 36% of its greenhouse gas emissions from energy. Moreover, the construction sector is responsible for over 35% of the EU’s total waste generation.

The Green Deal will profoundly change European industry and the construction and building sector.

Construction companies are already doing a lot to reduce emissions, but, according to recent studies, they only represent around 12% of the overall emissions of the construction process . Carbon emissions in a building stem from all phases and all actors of the life cycle. That is why it is important to focus on the whole construction value chain when looking at ways to decarbonise construction.

Green investments are still more expensive than traditional ones. We therefore need the continuous financial support of the EU and its Member States to ensure that such investments do effectively take place and that “no one is left behind”, in particular SMEs.

There is also a need to foster and strengthen research and innovation in the products, materials, machineries and processes that are involved in construction.

The digitalisation of the construction sector is essential for the transformation of the European economy.

Digital technologies not only improve productivity and reduce project delays but can also enhance the quality of buildings and improve safety, working conditions and environmental protection. A good example of what digital solutions can bring to the construction sector is BIM (Building Information Modeling).

To ensure that digital tools like BIM can unfold their full potential, we need the right framework conditions (e.g., ensure better data quality and data management, address challenges around intellectual property rights and cybersecurity…).

We also need to better assess and identify skill needs, support adequate training, up-skilling and re-skilling programmes and attract more young workers to the sector.

Only those companies that are willing to fully embrace both transitions – the green and the digital transition – will have a bright future and will continue to be successful on the market.

Reconnect with natural

microbiomes to enhance

resilience in a modern way

(Marco van Es)

What is the effect on human resilience of living with and eating of microbes from biodiversity?

The industrial revolution has reduced humen exposure to natural microbes. Our urban environment, buildings and playgrounds moved from green to gray. At the same time our food became more processed. These ‚developments‘ contributed tot o a reduction of the diversity of human gut and skin microbiomes. Interestingly, there is an accumulating amont of evidence that the diversity of the human gut microbiome is intimately linked with our health. For example, many chronic physical and mental diseases are linked with a poor microbial diversity. On the other hand healthy centenarians have a higher diversity of microbes in their guts than the control group. These findings form the essentials oft he revision oft he hygiene hypothesis, also known as the biodiversity hypothesis of health: reduced contact of people to the natural environment and ist associated microbial biodiversity may adversely affect the human commensal microbiota and ist immunomodulatory capacity. Microbial diversity connects human health with global health. This health perspective can change a mindset. It catalyzes the trend of recovering biodiversity as well as resilient human health. This paradigm can also result in the further elevation of human microbiome field. Inspirational key note talkes are provided by Marco van Es. Modern solutions to get in contact with microbes from nature are emerging. Examples are soil concentrates as cosmetic ingredients or sandbox supplements and breathable plant wallst o spread microbes in doors.

The development of CO2 neutral binders (Anja Buchwald)

Building industry is causing a substantial impact on the CO2 emissions, whereas the production of cement is responsible for the largest part of it. Pre-cast industry is asked by clients to come along with low CO2 concrete (products). This is the reason that concrete producers as well as clients struggle to built with CO2 neutral binders. Locking to the CO2 roadmaps of different countries/organizations etc. low CO2 of CO2 neutral binders are only find by applying carbon capture and storing (CCS). Alternative binders does not really found a place in them beside in the roadmap made from Netherlands. Therein Geopolymers are dedicated to deliver a substantial impact on CO2 reduction of the concrete supply chain. This can be explained by locking behind the calculations and arguments.

We do also see that an important task is put back to the construction industry itself. And rightly so! Strategies for making concrete with less cement and making concrete structures with less concrete offer a superior possibility to start saving CO2 without waiting on CO2 neutral binders and CCS. The building system where we are part of it, is note built on resource efficient use of cement and concrete. On the contrary cost structures and regulations lead to inefficient use of resources resulting in high CO2 emissions. As one result innovations are hardly get feet on the ground for several reasons. On the other hand a quick implementation of alternatives might as well as result in lots of damage due to lack of experience and meaningful measurement values to predict life time of concrete.

Anyhow there are possibilities to lower the CO2 of cements with alternative binders. The presentation will show results from the development and implementation steps done by ASCEM B.V. for its alkaline activated binders that is based on an precursor made by melting secondary resources. Why this binder may play an important role beside other alternative solutions will be discussed as well as given a comparison to other binder solutions by alkaline activation.

The presentation will give an overview and details of the development and demonstration steps covering the glass production, binder development and production as well as the application of different binders in several pre-cast concrete applications (foto). Obstacles and stumbling blocks on the way to successful implementation will be shown to give a complete picture about this innovation.

Italian precast industry progresses towards new Green Deal sustainability requirements, its strategic impact on manufacturing processes and final products improvements (Marco Pecetti)

The italian precast industry is committed to sustainability and is actively working towards sustainability in a number of ways including reducing carbon footprint, waste reduction, certification, innovation.

Methodology to evaluate the service life of concrete (José Rodriguez Soalleiro)

Durability is defined as the ability of a constructive element to withstand, during the service life for which it has been designed, the physical and chemical conditions to which it will be exposed and that could cause its degradation as a result of effects different from the loads and stresses considered in the mechanical analysis.

One of the most recognized features of precast concrete construction is its durability. This responds on the one hand to concrete, as a versatile and multiperformance material, which allows to extend its service life considering different variables from the design phase. And on the other to the prefabrication itself, as a direct consequence of producing the elements in the factory under an industrial procedure, much more meticulous and controlled compared with the execution on site.

However, the transformation towards greater sustainability of construction, the decarbonization of any related activity or the advance towards the circularity of construction materials and buildings and infrastructures, forces us to deepen the possibility of further extending durability. With the roadmap towards climate neutrality, durability will become even more important, since it will allow environmental impacts to be amortized in a longer period of time and will be an element of improving the competitiveness of companies that know how to optimize this essential parameter of sustainable construction.

In Spain, the design, construction and management of concrete structures is regulated by the Structural Code. As structures are reinforced and/or prestressed concrete elements, in general, and therefore, more susceptible to deterioration over time due to external agents, durability represents one of its most relevant chapters.

The standard presents two ways to meet the expected durability: a first prescriptive method, which depending on the exposure class of the elements, different parameters must be defined (types of cement usable and minimum cement content, maximum W/C ratios, concrete covers and minimum strength of concrete); and a second, more performance method. It is a model that the designer (could be the prefabricator himself) can follow alternatively and that is applied in carbonation corrosion (XC) or chloride corrosion environments (XS and XD classes).

This methodology makes it possible to estimate the residual service life of existing structures, as well as to help specify a concrete with a stricter dosage (for example, with a lower W/C ratio or with a higher cement content), or in the case of structures in very aggressive environments where the standard does not provide a fully defined durability strategy. It also allows estimating the possible reduction of covers when improving the performance related to the durability of concrete. The latter can be very interesting in the case of precast concrete elements, to the extent that the optimization of cover can lead to an adjustment of sections for the purposes of handling the pieces in logistics and execution.

The trend should be towards materials and constructive solutions that have the lowest possible value of the environmental impacts / duration ratio. This criterion is supported by the European sustainable building scheme LEVEL(s), whose indicator 1.2 is the global warming potential of the life cycle, and whose objective is to quantify the contributions of the global warming potential (GWP) of a building throughout its life cycle from the „cradle“ (the extraction of the raw materials that are used to construct the building) to the „grave“ (the deconstruction of the building and how to treat its building materials, i.e. recovery, reuse, recycling and disposal).

To facilitate the improvement of these two parameters that will become increasingly relevant and to be used for the manufacturers, we have designed in ANDECE two software that allow, on the one hand, the calculation of the indicators defined in the environmental declarations of precast concrete products, according to the European standard UNE-EN 16757; and on the other hand, a program that allows estimating the service life of prefabricated concrete structures according to the Spanish Structural Code.

A database for the French Precast Concrete Industry’s BIM objects library

(Rémi Lannoy)

More than six years ago, the concrete precast industry embarked on an exploration work around an emerging subject: the BIM. Now, we can look at this initiative with great curiosity. How could an industrial construction sector, specific to a particular material, imagine that BIM could become a subject of innovation and research? Supported by the FIB (French federation for concrete precast industry) and CERIB (Center for Studies and Research in the Concrete Industry), BIM broke into a field where the digitization of production practices was seen as a distant thing, and undoubtedly unsuitable.

However, one notion made it possible to establish the link between the concrete industry and BIM: the „object“. A manufacturer is familiar with this subject because it is exactly what he is selling, an object comparable to an article or a product. And this object is mostly used with others to form what are called „constructive systems“.

The first elements of development around BIM objects at CERIB originated in the habits of product description by manufacturers. We are talking mainly about catalogues, whether they are paper or digital. It is from these elements that CERIB has worked on the development of a database of generic BIM objects for the Concrete Industry, commonly known as BDD BIM G.IB. This work was complemented by the participation of CERIB in the POBIM project, launched by the PTNB (National plan for construction digitalization).

This database is now made up of 2 distinct entities which complement each other:

Set of properties and object models that will be likened to a data dictionary;

Objects library, derived from object models, allowing the definition of generic systems and components specific to the concrete industry.

Initially, the work around this database did not distinguish between the two components. They were centred on the characterization of generic objects, the definition of the initial models being relegated to the background. More precisely, the definition of the models intervened once the products to be integrated into the database had already been selected, described and characterized as BIM objects.

It was also during this period of development that our participation in standardization work increased. By integrating the French standardization committee for BIM (PPBIM), and by extension CEN/TC442, our understanding of the world of BIM objects was enriched by the many reflections that we carried out, notably within the WG4 Product Data Room. Finally, to consolidate our methodological approach to the creation and dissemination of BIM objects, we have conducted study partnerships with other construction stakeholders in the concrete industry environment to explore both uses of objects libraries and soft providers‘ solutions that focus on their distribution.

The intervention we propose aims to present as precisely as possible our understanding of what we might call today „Semantic BIM“, which is primarily concerned with the qualification of objects with a view to being used in digital models. This understanding is illustrated by our feedback on our work specific to the development of the concrete industry, with possible transposition to other industrial sectors.

Our work is primarily focused on the development and appropriation of common languages for the description of models and BIM objects. Our goal is to provide to the precast concrete manufacturers a library of generic objects and allow them to complete their specific catalogues using common description models. We also want to promote the development of a network of catalogues based on a precast concrete industry data dictionary. Our ambition is to integrate our dictionary into a harmonized network in order to make our model definitions consistent with other sector dictionaries.

Beyond our industrial sector, we want our data to be usable in an open digital environment by other construction stakeholders. The approach to our work by researching a common language is, in our opinion, the guarantee of making available open BIM data.

Digitalisation: Opportunities or mainly challenges? An engineering perspective

(Joseph Ickmans)

Being the only association representing the engineering consultancy industry in Europe, EFCA comprises 28 professional associations from 28 European countries. EFCA creates a network and business platform for its member associations and European firms and aims to positively influence EU legislation regarding the engineering consultancy business. Promoting fair competition and procurement rules is one of its goals. To cope with new challenges that derive from global digitalisation, including BIM among others, EFCA has created a committee that is dedicated to this subject.

The Digitalisation and BIM Committee of EFCA consists of specialists in both engineering and digitalisation. Within this committee, the focus is set on sharing information on recent developments, promoting digitalisation, and monitoring its impact on the engineering industry. Nowadays engineering consultants are not only involved in technical assistance during the phases of asset life cycles (due diligence, design, execution, operation & maintenance, and refurbishment or demolition) but they also cover different management roles in construction projects like technical management, project management, environment management, contract management, and project control. This gives engineering consultants extensive knowledge regarding processes and risks. The engineering consultancy uses this expertise daily to optimise productivity, ecological footprint, and good practice in construction projects, and thus actively assists its customers towards a safe, robust, sustainable digital future and a greener circular economy.

The main mission of the EFCA Digitalisation and BIM Committee is to support new developments in digitalisation by bringing this knowledge to the developers and hence ensuring compliance with existing processes and avoiding pitfalls. For this reason, EFCA endorses, and has actively supported initiatives like DigiPLACE, GAIA-X, and BuildingSmart International. Simultaneously the Digitalisation and BIM Committee also wants to share its joint expertise and actions taken with the other EFCA members and fellow European engineering companies and help them to find their way in the digitalisation ecosystem. We are convinced that the challenges the whole construction sector is already facing concerning climate protection, sustainability, and related topics can only be managed responsibly by an increased digitalization of the whole sector.

A few years ago, one of the actions organised involved the creation of the booklet “BIM and ISO 19650 from a project management perspective”. This booklet is intended to guide consultants and project managers in using ISO19650 and to advise on BIM-related aspects not mentioned in ISO 19650. The Committee members experience various national regulations and habits which made it possible to look at this matter from a more global (European) perspective. The creation of the booklet also highlighted the necessity of further actions to be taken regarding the risks that come along with this new digital era. Since that time, the Digitalisation & BIM Committee changed direction and took several steps to cope with these needs.

We intend to share our main findings, experiences, and recent actions at the 24th BIBM congress in Amsterdam.

Precast in Severe Seismic Zones (Ernesto Villalobos)

The earthquake of February 27, 2010 in Chile, measuring 8.8 on the Richter scale, affected an area of more than 400 km in the central part of the country.

In the first spectral analyses, it was demonstrated that, in soft soils and coastal areas, the phenomenon exceeded the design earthquake established in the current standard.

After the earthquake, it was possible to inspect the behavior of more than 700,000 m2 of prefabricated concrete structures and more than 200 bridges with prestressed beams that were in the areas most affected by the earthquake.

In general, despite overcoming the design earthquake, the structural functioning of industrial buildings designed under the Chilean seismic standard NCH236 of 2003 was satisfactory, presenting concentrated damage in designs made with standards prior to 2003 and in secondary elements such as concrete cladding panels.

In bridges and pedestrian walkways in areas of soft soils, the damage was concentrated in complete fall of boards (beams and slabs) by seismic displacements that exceeded the estimates of the design standards.

In tall buildings, designed under the NCh433 standard of 1972, the general performance was good, with exceptions where the insufficient amount of confinement armor in wall heads caused much damage and even the collapse of the Alto Rio building, Concepción.

This presentation shows the aspects of the design that worked well in the earthquake and what were the improvements in the designs of prestressed concrete industrial buildings and bridges to ensure good performance in the most severe earthquakes.

The desing recommendations for bridges with isostatic prestressed beams was assuming large deformations and ensuring that’s the deck is confined between lateral stops strong enough to withstand seismic forces. The use of crossbars in the support line of the beams and intermediate crossmembers is mandatory. The use of deck solutions in continuity is favored, even more so when the bridge has little travel.

For new industrial hall designs, it is required to limit deformations through rigidity and to supply ductility in critical sections. The structure will be demanded by large deformations, so the detailing of the reinforcement is essential to ensure that each column and beam can withstand those deformations and also grant additional strength that will help maintain the integrity of the structure in a severe event.

Flood management is becoming an increasing problem in urban areas due to several factors (Oscar Ekefäll)

Rapid urbanization leads to the expansion of cities and the conversion of natural land into hardened surface where water cannot infiltrate the ground. This results in reduced permeable surfaces, such as soil and vegetation, that can absorb rainfall. As a result, rainwater flows quickly over impermeable surfaces, overwhelming drainage systems and causing floods.

The changing climate patterns contribute to more frequent and intense rainfall events. Urban areas are particularly vulnerable as they are often ill-equipped to handle excessive rainfall within a short period of time. Climate change also leads to rising sea levels, increasing the risk of coastal flooding in low-lying urban areas.

Many urban areas lack sufficient infrastructure to manage stormwater effectively. Outdated or undersized drainage systems, combined with poor maintenance, can lead to blockages and overflow during heavy rainfall. Insufficient investment in flood control measures exacerbates the problem.

Urban areas are densely populated, with a high concentration of people and infrastructure. This density amplifies the impact of floods, putting more lives and property at risk. Limited space for water storage or runoff exacerbates the challenges of managing excess water.

In order to address the challenges of flood management in urban areas, several concrete solutions can be implemented.

To make sure that the pipes we lay today can handle the increasing amount of stormwater the pipeline system must be dimensioned by the increasing amount of stormwater. The modern Concrete pipe has a service life of at least 100 years so they must be large enough to handle the stormwater 100 years into the future.

Precast concrete reservoirs play a crucial role in flood management by providing effective storage and control of excess water during heavy rainfall events. These reservoirs are specifically designed to capture and retain large volumes of water, mitigating the risk of flooding in urban areas.

One of the primary advantages of precast concrete reservoirs is their durability and strength. Precast concrete structures are built to withstand extreme weather conditions and hydraulic pressures. They can resist the forces exerted by water and remain structurally sound, ensuring the reliability and longevity of the flood management system.

Precast concrete reservoirs offer flexibility in design and construction. They can be customized to suit specific project requirements, including size, shape, and capacity. This adaptability allows for optimal utilization of available space and integration into the surrounding environment. Precast concrete components are manufactured off-site under controlled conditions, ensuring consistent quality and dimensional accuracy.

The speed of construction is another advantage of precast concrete reservoirs. Since the components are prefabricated, on-site assembly and installation are relatively quick and efficient. This accelerated construction process minimizes disruption to the surrounding area and reduces the overall project timeline.

Precast concrete reservoirs can incorporate additional features to enhance flood management capabilities. This may include the integration of water control gates, inlet and outlet structures, and overflow systems. These features enable the controlled release of stored water during non-flood periods and prevent overflow during peak flow events. Easy to combine with oil separators that match the controlled release rate of the water to prevent any oil leakage.

Maintenance of precast concrete reservoirs is relatively straightforward. Regular inspections, sediment removal, and cleaning ensure that the reservoirs continue to function effectively.

The results of the Italian Research on fire performance of masonry and the shared action of a Companies Group of Assobeton (Chiara Crosti)

The Blocks and Paving Group gathers manufacturers of concrete interlocking paving and masonry blocks and was established in Assobeton, the Italian Association of Precast Concrete Manufacturers, in the 90s. At the time being the group has the thirty most representative companies on the national market.

The team philosophy, the sharing of experiences at standardization level and the common vision on the technical objectives useful for transparency of the market have allowed the Group to develop a specific research program finalized to evaluate the fire behavior of non-load-bearing masonry made of concrete blocks and overcome some limits set by regulations and standards.

Starting from the analysis of the Eurocodes up to the Italian Technical Construction Standards and the Italian Technical fire prevention standards (with its Appendix “National”), the fire resistance performances of construction products and elements may be determined based on the results of:

a. tests,

b. calculations,

c. comparison with tables.

In the case of non-bearing masonry, the comparison with tables defines an applicability limit in height of 4m; the experimental method instead with EN 15254-2:2009 “Application extended results from fire resistance tests for non-load-bearing walls” allows to add the results of a 3x3 m sample up to 8 m as long as the slenderness is less than 40 (therefore it has a thickness of 20 cm) and the deflection of the test specimen at half height is less than half of the thickness of the wall.

As far as the analytical method is concerned, the only reference for performing the calculations is represented from Eurocode 6 (EN 1996-1-2 „Design of masonry structures - Part 1-2: General rules - Structural design against fire“) and the relevant Appendix “National”. However, the calculation is limited to load-bearing masonry, and it is often necessary to validate the analytical model with specific experimental tests.

It follows that, for non-bearing masonry, it is necessary to resort to criteria of evaluation according to an experimental or tabular method which, however, has a limitation of rather strong applicability on the maximum heights of the masonry.

It would be considered useful to deepen the experimental method by organizing tests on specific geometry of walls, with the aim of being able to obtain a series of data that allows to define a law of extrapolation of the height of the masonry made of concrete blocks. With a planning of experimental tests supported by finite element modeling, in fact, it could be possible to better understand the behavior of non-load-bearing walls beyond the height limit defined by the method tabular (8 m) and from experimental tests (height less than 8m or in any case slenderness less than 25).

A first step in this direction has been made taking as references the results of three experimental tests and developing thermal and structural analysis using the finite element calculation code SAFIR.

By means of a macro-modeling of these three types of concrete blocks, it was possible to assess the thermal distribution and make considerations about the structural response of the masonry. As the wall was considered heated on one side it was possible to assess the distribution of the non-linear thermal stresses of the concrete section with the increasing of temperature and to make assumption about the structural behavior of the non-load bearing masonry under study.

The next step is to perform experimental tests by using a sample of masonry with dimensions of 4 m (length) x 6 m (height), to validate the numerical modeling and obtain a reliable tool of calculation for the associated companies. At the time being, tests are in progress.

Carbon Capture in the cement industry

(Rob van den Meer)

Background

Cement is the basic material for the concrete sector. The cement industry in Europe is an energy intensive industry with significant emissions of Green House Gases, especially CO2. From 1990 to 2020 the production of cement covered by CEMBUREAU decreased from 232 to 195 Mtonnes per annum. At the same time the emissions of CO2 decreased from 168 to 121 Mtonns/a which correponds to about 27%. Impressive, but not enough.

CEMBUREAU roadmap

In 2013 CEMBUREAU published its first carbon roadmap. That roadmap has been completely renewed and updated in 2020 with the publication of the CEMBUREAU Carbon Neutrality Roadmap 2050. In the title you see the ambition: Carbon neutrality in 2050. The concept is based on the so called 5C approach:

Clinker

Cement

Concrete

Construction

Carbonation

All 5 levers in this roadmap are decisive for the decarbonation of the cement industry. And all levers are targetted in detail.

Carbon capture

Compared to other sectors one of the major challenges of the cement industry is formed by the process emissions. Cement is made from limestone, and during the production of cement CO2 is emitted from the raw material. That process emission is unavoidable when you want to produce cement. Currently the process emissions form about 60% of the total emissions.

In the package of emissions reductions of the cement industry carbon capture is a fundamental technology to abate the emissions. The concept of carbon capture is that CO2 from the exhaust gases is extracted and either used or permanently stored in products or geological formations. As such the concept of carbon capture with geological storage is known in other sectors, but not yet at commercial scale in the cement industry.

Since 2007 a lot of research & development has been done on first the capture of CO2 and second on the use and storage of the captured CO2. In 2024 the first demo-scale carbon capture installation in the cement industry will be commissioned Norway at the Brevik cement plant of Norcem. The captured CO2 will be geological stored in the underground of the North Sea in Norway. Many ohter capture installations will follow. Part of these installations will capture for geological storage, others will use the CO2 for production of aviation fuels and other carbon based materials. Finally a third possibility for the use of the captured CO2 is the mineralization of aggregates and the recarbonation of concrete.

In the CEMBUREAU Carbon Neutrality Roadmap 2050 the importance of the carbon capture is stressed by the fact that 42% of the projected emissions reductions will come from carbon capture.

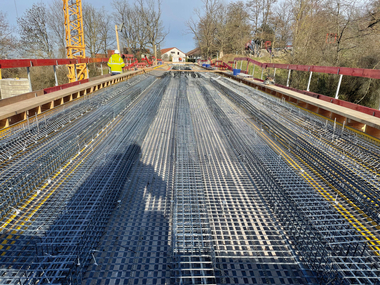

New methods for the material and cost efficient bridge construction with precast elements (Johann Kolleger)

30% of the construction costs compared to the originally planned steel-concrete-composite bridges could be saved in the construction of Lafnitz and Lahnbach bridges in Austria. The usage of thin-walled bridge girders (length 36 m, wall thickness 70 mm) and the first application of the balanced lowering method resulted in large savings of construction materials and consequently in reduced project costs. The following lessons were learned during the construction of Lafnitz Bridge and Lahnbach Bridge:

(i) The erection of the longitudinal girders with the balanced lowering method was a fast and efficient method.

(ii) The production of the deck slab with a conventional formwork carriage was a slow process. In the case of this project only 15 m of the deck slab were produced in one week.

Based on the experiences, which were gained during the construction of Lafnitz and Lahnbach bridges, a precast deck slab element was developed. A deck slab element consists of thin plates, which are connected by two transverse beams. During the construction of the deck slab, the deck slab element fulfills the following functions:

(i) It provides the formwork for a section of the deck slab.

(ii) It carries its own dead load, the weight of the in-situ concrete, which is placed on top of the deck slab element, as well as the weight of the workers, who are positioned on the deck slab element during the casting of the top concrete layer.

Precast deck slab elements enable a very fast production of the deck slab of steel-concrete-composite bridges. The deck slab element can be placed on top of the steel structure with the aid of a crane or a transportation carriage. Up to 30 m of the deck slab can be produced per day.

In the LT-bridge construction method thin-walled longitudinal girders (L), transverse deck slab elements (T), and a layer of concrete, cast on top of the deck slab elements, are used. The longitudinal girders and the deck slab elements are connected by starter bars and the in-situ concrete in such a way, that a monolithic concrete bridge is obtained in the final state.

Simplified construction process of one span of a LT-bridge: In the first construction step two longitudinal girders are placed with the aid of cranes or a launching gantry. In the following step, seven deck slab elements are installed on top of the longitudinal girders. The entire transverse reinforcement, the stirrups and the bottom longitudinal reinforcement have previously been installed in the deck slab elements in the precast plant. The utilization of the precast structural elements (longitudinal girders and deck slab elements) and the minimization of the reinforcement, which has to be installed at the construction site, enables the erection of bridge spans with a length from 25 m to 60 m in a weekly cycle.

The first LT-bridge was constructed in September 2022 for ÖBB Infrastruktur AG. The superstructure of the single span frame bridge could be erected within three and a half days. Compared to the initial design 40% of the concrete mass of the superstructure could be saved. Because of the successful first application of the LT-bridge construction method, two more bridges are currently designed with this method in Austria.

75% material savings in foundations by using 3D-printing technology –

additional business line

for pre-casters?

(Topi Paananen, Fernando de los Rios)

Introduction - why are mate-

rial savings important, gener-

al examples

When discussing about the planetary savings and CO2 savings, the very first question when starting to construct an object is the following: is the new structure really needed? The biggest saving is not coming by selecting a building material X or Y, but to omit the construction of a new structure, or by renovating an existing structure.

If the option to build a new structure is selected, the following questions constitute the next level of questions: A) Could we optimize the amount of used building materials, and thus use less of them? B) Which building material is going to be used?

The biggest savings of CO2 are coming, regardless of the material used, from the savings of the cubic meters or kilograms of the materials in question. The factors leading to the material savings are a) clever structural design and b) technology used.

There are several clever ideas and concepts that save materials, particularly in heavy structures such as foundations, or in the first levels of the buildings.

Peikko has experience on many material-saving design concepts, such as in wind-turbine tower foundations where existing soil/rock is being utilized or punching shear reinforcement used in various slabs and slim-floor structures enabled by composite beams. All these examples lead to reductions of material and weight and thus significant lower CO2 content.

3D Printing to enable clever

design, less materials and

more off-site work

During 2022 Peikko saw an innovative design combined with innovative 3D-printing technology, and the research co-operation between Peikko and Hyperion Robotics begun. The Hyperion Robotics’ foundation concept, in Peikko’s view, is based on a) clever structural design in an area where there has recently been no major innovations, and b) a relatively new 3D printing technology used to meet the requirements of this clever design.

In addition to the above, the concept promotes the off-site work, moving some part of the work of making foundations into factory-like environment.

When Hyperion Robotics was called by Iberdrola, one of the largest renewable energy companies in the world, to help them automate and optimize the construction of their energy transmission lines, it was realized that 70% of the Iberdrola concrete structures go underground, and most of them are foundations.

In most cases foundations are massive monolithic blocks of concrete, and they are almost everywhere - from small homes to residential and commercial buildings all the way to industrial and infrastructure projects. More than often these structures are overlooked because one does not see them as regularly as buildings because they are underground, but the amount material used and CO2 generated is still significant.

While collaborating with Iberdrola, Hyperion Robotics realized that it could help them save a large amount of materials (75% volume reduction) when building reinforced pad foundations by using the benefits of its design optimization software and 3D printing technology, significantly reducing their project heavy capex, demonstrating the reduction of production lead times and reducing CO2 by more than 50%. This led to less volume and thus less concrete, therefore less cement and finally less embodied carbon.

Precast technology is efficient when producing concrete products on a massive scale, but mass customization and design optimization are still a big question when using conventional moulding technology or formwork. The concrete 3D printing could be seen as a new technology that could generate new lines of business for pre-casters, not only enabling the new design concepts, but also mass-customization.

Rudus Biodiversity Programme - Experiences and Opportunities for Precast Concrete Sector

(Terhi Rauhamäki)

Rudus Oy is a leading company in Finland to produce rock-based building materials. Rudus operates widely across Finland and has a comprehensive network of ready mixed concrete plants, concrete product plants, gravel pits and rock quarries, and reception points for recyclable building materials such as used concrete, bricks and green soil.

Since 1999, Rudus has been part of the Irish CRH Group, which operates worldwide in the building materials sector. CRH operates in 28 countries and employs 71,000 people in approximately 3,200 locations. CRH is the largest building materials company in North America and the second largest worldwide.

Environmental Responsibility

The vision of our environmental responsibility strategy is to be part of emission-free construction. We want to influence the future by creating low-carbon solutions, supporting biodiversity and promoting the circular economy. We have identified four focus areas of environmental responsibility for Rudus‘ operations: carbon footprint, carbon handprint, circular economy and biodiversity. Goals and key measures have been defined for each focus area. In addition to these, our commitment to the goals of our parent company CRH is the basis of our entire business.

Biodiversity Programme – Rudus LUMO Programme

Biodiversity, the diversity of nature, is a vital condition for the survival of life on Earth. In December 2022, the UN Nature Conference reached an agreement on stopping the loss of nature, which is why regulation related to nature will increase even more and become more and more relevant for companies. Actions to prevent loss of nature are required, among other things, in the EU Taxonomy Regulation and the future requirements for sustainable development reporting (CSRD, Corporate Sustainability Reporting Directive) and related reporting standards.

Rudus wants to contribute by preserving Finnish biodiversity and supporting nature to adapt to climate change. In 2012, Rudus launched the LUMO programme. The central goal of the programme is to make the biodiversity of our operating sites more valuable through our operations than they were at the beginning.

We have thousands of hectares of land at our disposal. Some of this consists of open areas for aggregate extraction and some contains factory buildings. Along with production, we implement biodiversity measures and aftercare in these areas in ways that account for biodiversity. For example, an original, open and dry ridge landscape is a rarity in modern Finland. However, similar nature can be found in the sand pits of aggregate quarries. By preventing or slowing down the afforestation of pits, a suitable environment is created for rare dry and hot open area plants and endangered insects. On factory plots we have e.g. built birdhouses and shaped slopes, which have been planted with endangered plants suitable for the particular area. We also produce concrete products for stormwater management and the construction of green environments in urban environments.

Having been implemented successfully for over ten years, the LUMO programme has become a practical approach for Rudus. Our employees are committed to the programme and appreciate its importance in increasing biodiversity.

The success of the programme was possible by the strong commitment of Rudus; management to the set goals and chosen operating methods. An important part of the successsful programme has also been the creation of an extensive network of experts and stakeholders, as well as collaborative projects and various experiments and their monitoring.

In ten years, the Rudus LUMO programme has developed into a real operating model with a network of experts, trained personnel, mapped opportunities and challenges, and defined goals.

Future

Rudus continues to be a pioneer in the construction industry as a protector of natural diversity. Rudus has joined the SBTN Corporate Engagement Programme in 2022 and has started setting, implementing and tracking progress on science-based targets for nature.

The LUMO program has addressed the nature impacts of direct, our own activities. Now the Science-Based Targets for Nature will also bring into consideration supply chains and the global impacts of various measures. The SBTN programme sets completely new goals for us. With it, we both develop and expand our LUMO programme and prepare ourselves for the requirements of future EU regulation.

The Re-use of girders

(Wietse de Jong)

This story of reusing overpasses and concrete briges is about high-quality reused object and parts. Our partners aims to achieve a high-quality reuse of existing viaducts in the form of new circular viaducts. Girders are a main component in this.

This started with a The Strategic Business Innovation Research (SBIR)

The Strategic Business Innovation Research (SBIR) Circular Viaducts is an innovation request by Rijkswaterstaat (the Dutch Ministry of Infrastructure and Water Management) aimed at accelerating the transition towards circular construction. Ten consortia completed their feasibility studies in 2021 and presented the results to various Rijkswaterstaat projects on March 24, 2021. Based on these presentations, an independent assessment committee selected three consortia, namely Closing the Loop and Liggers 2.0, which focus on testing and realizing a prototype viaduct consisting of reused components from existing viaducts. The societal impact of circular viaducts is significant and directly contributes to Rijkswaterstaat‘s climate goals of working in a circular manner by 2030 and achieving full circularity by 2050.

Currently, viaducts in the Netherlands are typically demolished after 40-50 years due to changes in the area or expansion, after which the old girders are sent to demolition. High-quality prestressed precast concrete, on average, has a lifespan of 200 years. This means that even after 50 years of intensive use, these types of girders can still meet the highest standards and can be safely incorporated into a new bridge or viaduct. This preserves the function and value of the girders while also saving on primary resources, CO2 emissions, and Environmental Cost Indicator.