High-performance mixer for Autoclaved Aerated Concrete production plants

Masa builds efficient and durable production plants for the building materials industry. The quality of the end products manufactured there is influenced by many factors. A decisive process step is the mixing of the materials. This will be explained here in Part 2 of this technical article (AAC mixer).

When high-quality autoclaved aerated concrete is produced, all required raw materials come together for the first time in the high-performance mixer. In AAC production the mixer determines the quality of the finished products and is the heart of the complete plant thus. Although the performance data of the previous Masa mixers are very high already, Masa wants to enable their customers to prepare for increasing requirements of the future building materials market. Growing quality and density requirements as well as an optimized energy consumption at optimal cost are the tasks that have to be accomplished. To meet these requirements further on, the mixing process has to be optimized continuously. Based on a wealth of experience and in close cooperation with the plant operators, Masa has now developed a new generation of the high-performance mixer as today’s forward-looking solution for tomorrow’s autoclaved aerated concrete production.

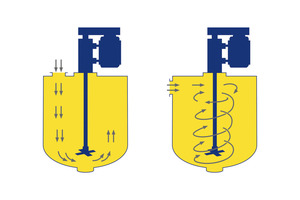

For the development of the new high-performance mixer HPM 2, the service experience and customer feedback were considered and evaluated. This resulted in the optimization of various details which in total meant a considerable improvement, compared to previous mixers. The main features are described in Fig. 1.

Way and energy optimization

For the preparation of the autoclaved aerated concrete compound, slurries and water are mixed with the weighed raw materials lime, cement, gypsum (anhydrite) and aluminium powder or paste. The Masa high-performance mixer installed above the casting mould has the task to stir the materials homogeneously.

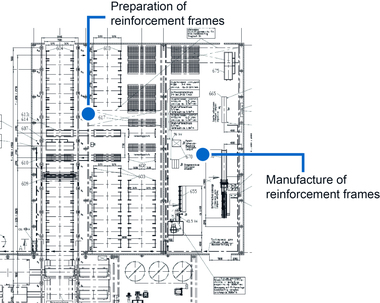

To begin with, the stability of the material flow from the raw material scales to the mixer has a direct impact on the autoclaved aerated concrete production. Only when the raw materials are transported to the mixer constantly, reliably and in the correct order, the AAC production can proceed according to plan. Pipes are used to feed the raw materials into the mixer. The routing of these pipes is optimized so that they run vertically as far as possible and avoiding bows/curves. This systematically minimizes the risk of sediments and obstructions inside the pipes.

To achieve a high product quality, the compound generated in the mixer has to be as homogeneous as possible. For this, the feeding of the main components of an autoclaved aerated concrete recipe – sand slurry and return slurry – plays a decisive role. In most conventional mixers, the slurries are fed in vertically. The Masa engineers calculated several possible positions and angles for an optimum raw material supply and, after various simulations, carried out live tests with the most promising solutions. As a result, the inlet opening for slurries and process water is positioned in the side of the mixer. The flow direction of the liquid components is arranged tangentially and thus in the direction of rotation of the special stirring device of the mixer. With the optimization of the adjustment possibilities for feeding diameter, feeding speed, and feeding angle, the engineers could reduce the inertness during mixing, compared to the conventional vertical feeding of the slurries. This helped to considerably improve the energy efficiency of the system.

Another means to reduce the energy consumption is the circumferential speed of the stirring device. In conventional mixers, the speed of the stirring device is mostly constant. In this case, the components added to the mixing process step by step are all mixed at a constant speed. With the HPM 2, Masa considers the fact that a particular feed level has an impact on the work to be done by the stirring device. The more material inside the mixer, the higher the engine load. The use of a frequency converter at the drive unit enables a steplessly adjustable revolution speed. The Masa mixing plant control system automatically adjusts the various speed levels of the stirring device stored in the individual recipes.

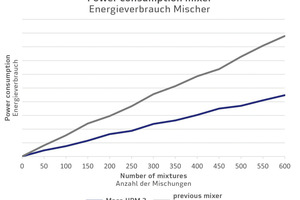

More than 40 % saving of energy in the mixing process

With the described optimizations, the HPM 2 formidably reflects the economic minimum principle: The defined target, in this case the generation of the highest possible homogeneity within the prepared autoclaved aerated concrete compound, is achieved with as little resource input as possible. Compared to previous mixers, the power consumption could nearly be halved. With special power consumption recording devices, Masa could measure the consumption of a production day at a customer’s plant. This measure helped to reduce the original motor capacity of the stirring device drive from 75 kW to 37 kW, a clear advantage for the profitability of an AAC production plant using a Masa HPM 2 and a considerable contribution to increase the sustainability.

Operating cost optimizing features

From a cost perspective, the described improvements have a positive impact on energy costs. Looking at the operating costs, however, the maintenance costs should not be left out of consideration either.

The equipment of the stirring device with a frequency converter as described above has another advantage: The abrasive wear and tear is reduced, this automatically means that the service life of the stirring device (mixing blade) is prolonged. Field reports from Masa production plants clearly show this.

When a mixer blade has to be replaced, the HPM 2 has a large lateral maintenance access that enables a simple, safe and particularly fast replacement. The shutdown period of the mixer and the production downtime can considerably be reduced thus.

At the new HPM 2, the drive shaft as well as the mixing tool are balanced. This means that the drive shaft does not require additional support in the lower section of the mixer. This is a great advantage when the mixing tool has to be changed. As there is no additional bearing block, the replacement can be carried out much faster and easier. This also reduces the downtimes of the mixer.

After the mixing process has been completed, the mixture is fed into the casting mould through a casting device. The mixer and the casting device are automatically, and in variable intervals, rinsed with water. This cleaning process is essential to make sure that the new mixture is not affected by remains of the previous mixture. From a water tank positioned above the mixer, the rinsing water is led into the mixer through a piping system by hydrostatic pressure. Up to a certain degree of pollution, the rinsing water is reused and pumped back into the rinsing water tank before it is finally fed into the return slurry system. To intensify the cleaning process, the Masa high-performance mixer is equipped with a special rinsing water distributor. This reduces the time required for the cleaning process so that the next mixing cycle can start sooner. Thus, Masa can supply a sophisticated system that, on the one hand, increases the operational availability of the mixer and, on the other hand, enables a wastewater-free use of the resource water.

Product-related optimization

Autoclaved aerated concrete is a building material with a high solidity. As a solid building material, it has excellent heat insulation powers at the same time. Based on its low raw density and high proportion of air, it is generally characterized by a relatively high heat capacity and low thermal conductivity. However, the U value (heat transfer coefficient) of AAC is not always the same. The heat insulation effect of the building material mainly depends on the raw density: A lower raw density reduces the thermal conductivity and improves the insulating characteristics thus. As a consequence of rising energy costs and growing requirements on the building materials, the market share of autoclaved aerated concrete products with as low as possible densities has grown. The preparation of a mixture for AAC with a raw density of 300 kg/m³ eg. requires special care, however. The sheer volume of the liquid compound in the mixer is less than that for products with a higher raw density. But the mixer has nevertheless to be capable to achieve a continuous homogeneity of the mixture for such small quantities as well. In most cases, conventional mixers cannot accomplish this to the full extent. In the developing phase, the geometry of the mixer was designed in that way thus that even small quantities are mixed perfectly.

The design engineers are proud that they could fundamentally improve the new HPM 2 in 4 categories: Approx. 40 % less power consumption, considerably more intense rinsing effect, less mechanical wear and tear and considerably reduced down times in maintenance intervals.