An alternative reinforcement material in concrete construction

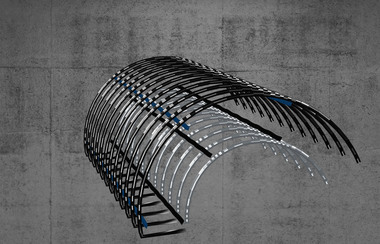

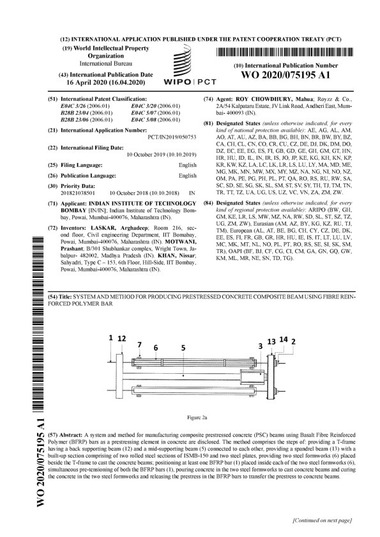

Fibre-reinforced polymers (FRPs) consist of numerous fine fibres which are unidirectionally embedded in a polymer matrix (e.g. epoxy resin). Currently glass or carbon fibres are mainly used for the production of FRP reinforcement for concrete members. Basalt fibers are the subject of current research projects and show mechanical properties similar to those of glass fibres. The application potential of FRP reinforcement in highly corrosive environments, such as harbours, bridges, multi-story car parks or industrial plants, is very large. This corrosion-resistant reinforcement can prevent damage due to reinforcement corrosion and increase the durability and sustainability of concrete structures.

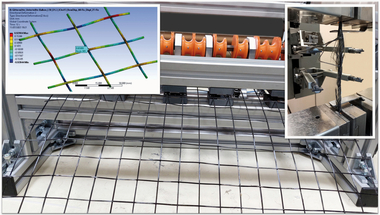

Basalt-fibre reinforcement (BFRP) also has a very low coefficient of thermal conductivity and electromagnetic neutrality, which makes its use in relevant areas such as laboratories, power plants or hospitals useful. We also see significant potential for the large-scale use of BFRP in conventional building construction (for example for ceiling slabs) owing to its low material cost and weight. Since the material properties of BFRP reinforcement differ significantly from conventional reinforcing steel, the design and construction guidelines of reinforced concrete construction cannot be transferred to this new type of reinforcement without verification or adaptation. For this reason, experimental investigations on the material itself and on small-scale concrete specimens (bond behavior) and full-scale concrete specimens (load-deflection behavior) are necessary in order to derive design rules for the practical application of these concrete components.