In-house exhibition at the newly built-up Sønderborg production site

In 2022, the course of the Omnicon Group was set towards the future. A fire damage in the previous year gave the go-ahead for a complete reconstruction. This took place at the location in the Danish Sønderborg. A maximum level of sustainability was ensured by complying with the latest environmental standards. Hence, Omnicon has now more than 6,000 m² of storage space, spread over four warehouse facilities, and two production halls covering a total of nearly 3,000 m².

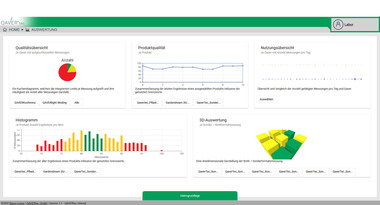

In the course of the reconstruction, both the logistic processes were optimized and an investment was made in a modern water treatment plant. Another focus is on the production and the development of environmentally-friendly products, such as a new generation of admixtures for reducing the cement content in concrete products, sustainable pigments, coating products free of micro-plastics and the Qavertec technology adapted to the digital age for quality testing of freshly produced concrete goods and the determination of the water contents in mineral building materials.

The individual steps of the modernization hereafter:

New construction of an administration/laboratory building covering more than 1,000 m²

New construction of a warehouse building covering more than 2,000 m²

New construction of a production hall covering more than 1,500 m² – apart from the modern production plants, the water treatment plant is situated there. This plant enables making use of 70 to 80 % of the surface water in the production process and for washing the containers. For this purpose, water is collected on the company premises of approx. 4 hectares and is then prepared for utilization in an automated, low-energy process. This allows the utilization of approx. 7 million liters/year, reducing the use of potable water from ground water resources.

In addition, Omnicon is treating the waste water collected from the container washing process, while separating solids from water. This reduces waste materials considerably and saves costs. It is, moreover, ensured that water is quickly returned to the water cycle again. Approx. 400 - 500 t of washing water are arising per year, it consists of about 1/3 of sludge and 2/3 of water.

In-house exhibition organized

The Omnicon Group organized an in-house exhibition in Sønderborg on April 12th. Highlights were the factory tour and an exclusive evening event under the motto: „Innovative and sustainable into the future“.

The following new developments were presented to the numerous guests coming from Denmark and from abroad: Low CO2 values in the production of concrete goods, new types of pigments with low contents of heavy metals and low GWP values, polymer-free recycling coating adapted to the Green Deal for concrete roof tiles, modern concrete admixture series for the new generation of cements, testing devices for recipe optimization and resource conservation, digitalization of moisture determination of concrete and aggregates samples as well as coatings for fire protection, sound damping and wood-based materials. Further topics discussed were methods towards a concrete blocks free of efflorescence, analytics for the determination of heavy metals and harmful substances in cement and other raw materials and DGNB-certified release agents.

Sönke Hansen, Sales Manager at Omnicon, answered the questions of the BFT editor in a short interview held on site in Sønderborg:

BFT International: Mr. Hansen, when was Omnicon founded?

Sönke Hansen: Omnicon was founded at the turn of the year 1994/1995 at the Sønderborg location.

BFT International: What is the company producing?

Sönke Hansen: We produce pigments for the coloring of concrete, concrete admixtures for improving the concrete properties as well as surface protection systems and coatings for paving blocks, roof tiles and mineral slabs.

BFT International: How many employees does Omnicon have?

Sönke Hansen: Omnicon has a workforce of about 30 people at this location and as a Group approx. 50 to 60 employees.

BFT International: How large are the quantities or capacities Omnicon has and/or produces?

Sönke Hansen: Omnicon has an annual production capacity of approx. 20,000 tons at the Sønderborg location currently.

BFT International: The actual cause for the new construction was a fire about three years ago. Can you give more details on this incident?

Sönke Hansen: After conclusion of the investigation, the self-ignition of a battery of an Ameise electric pallet truck that had been parked in the evening, was confirmed as cause of the fire. We lost approx. 65 % of the production facilities, however, owing to conversion measures taken in the production areas not affected and using still available goods in stock, we were able to supply our customers within two weeks again with products.

BFT International: How long did the reconstruction take?

Sönke Hansen: The demolition and reconstruction up to today‘s status took only 26 months including permission and planning. I think that was an amazing performance of all those involved.

BFT International: Dr. Hansen, many thanks for the conversation und much success furthermore!

Interview: Dipl.-Ing. (FH) Silvio Schade, Editor-in-Chief BFT International