Infra Tunnel relies on the Alkus formwork panel for the „H10 – Tunnel de La Clusette“ project

The Alkus formwork panel fully made of plastics has been used for the construction of the safety tunnel of Tunnel de La Clusette in the Swiss canton of Neuchâtel. The Infra Tunnel SA construction company used the Alkus GM6 on the tunnel carriage made by Rubrika and partially in the Peri tunnel formwork as well. With success: The formwork panel provided the flexibility required as well as the perfect finish.

The 1km-long Tunnel de La Clusette no longer met the required safety standards after 50 years in service. Therefore, the tunnel has been under renovation since 2021 as part of the „H10 – Tunnel de La Clusette“ project. In addition, a safety tunnel is under construction in parallel to the road tunnel, for evacuating the same in the event of fire. The completion of the project is scheduled for 2026. Client is the „République et Canton de Neuchâtel“. The contract for the construction of the safety tunnel including the connection tunnels to the main tunnel was awarded to the Swiss construction company Infra Tunnel specialized in underground construction works.

The appropriate fromwork facing for high requirements

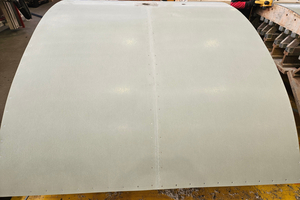

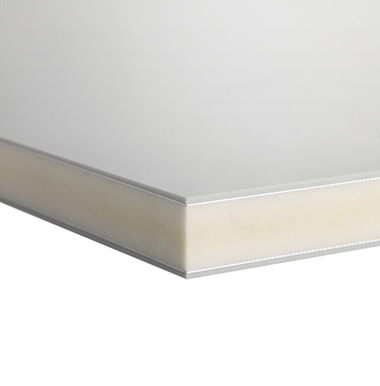

A perfect concrete appearance was required; that is why the selection of the formwork facing played an important role in the project. Moreover, a formwork panel had to be chosen for the curved special formwork units that adapts to the shapes without any problems. Therefore, those responsible for the project decided to use the glass fiber reinforced solid plastic panel Alkus GM6 for the formwork works on the safety tunnel and partially also on the connecting tunnels. The six millimeter thick formwork panel supplied by Alkus AG located in Liechtenstein is flexible, but rigid simultaneously and meets the high requirements on the surface quality without any problems too. Due to its ruggedness and durability, it eliminates the need to replace the formwork facing, being particularly time-consuming in tunnels.

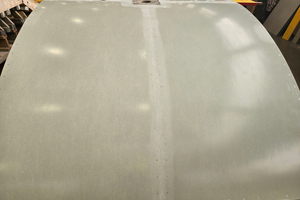

Rubrika formwork carriage riveted directly to the Alkus panel on site

Alkus GM6 combined with the tunnel carriage of Rubrika was used for the construction of the safety tunnel. „Rubrika has been a satisfied customer of Alkus for several years and therefore they knew our products and their advantages and applications very well,“ states Michael Tschenett, General Manager of Alkus AG. The Rubrika formwork carriage was riveted with the Alkus GM6 on site directly and not welded but joined directly. Those responsible have riveted the panels in a narrow grid, so as to avoid that concrete may flow in – which in turn would have impaired the requested surface result.

Matt formwork panels for the perfect finish

For the connection tunnels of the main tunnel and the safety tunnel as well as the parking bays, the tunnel formwork made by Peri was used and – on the initiative of the client and Infra Tunnel – the Alkus GM6 formwork panel made of solid plastic was used partially too. A team of Alkus AG supported Peri Switzerland at the location in Ohringen near Winterthur with the formwork.

Alkus convinced with perfect results

The results look quite respectable: Thanks to covering the special formwork with Alkus GM6 panels, the requested demanding results could be realized in all cases without replacing the formwork facing. “We are very satisfied with the feasibility of the GM6 panel as well as the top result,” states Fabian Epiney, head of special formwork construction at Peri Switzerland.