Innovative resource-saving precast construction using concrete trusses

Particularly in precast construction, which is characterized by its cost effectiveness, high-quality production alternatives, including self-compacting concrete, open up a wide range of opportunities for constructing sustainable buildings and structures in the future.

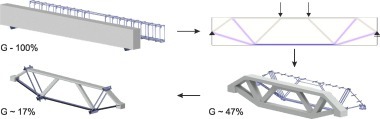

Just recently, for example, Laumer Bautechnik GmbH designed and produced concrete trusses for roof structures. Slender cross-sections in the strut area reduce concrete consumption considerably

and thus lead to substantial weight savings. In addition, this design

reduces the amount of reinforcement required in this area to ensure

structural integrity and stability. Combined with innovative fasteners,

long precast elements can thus be produced in a “piecemeal” process, dividing them into several sections. This results in precast elements with reduced lengths that can be transported to the construction site more easily and at lower cost. These are then connected on site, for example with reinforcing steel couplings. This concept simplifies formwork fabrication while achieving resource savings since the forms need to be built only for the shorter truss sections and can thus be reused several times. Unlike other construction methods, precast elements meet fire safety specifications without requiring additional protective measures thanks to their concrete cover.

Yet structural stability is but one aspect while aesthetic appeal is the other: On the one hand, the resolved truss area makes the three-dimensional roof structure appear light by design; on the other, it also impressively reflects the engineering approach to achieving the load-bearing effect using compression and tension members. Truss systems can thus be a useful alternative particularly if wide spans are needed.

The concept of “piecemealing” the trusses and connecting the segments on the construction site makes it possible to manufacture wide-span systems also at precast plants with restricted form lengths.